Aerospace

For Aerospace Parts Requiring Ultra-Precision Accuracy

Precision matters in aerospace. Whether for rockets, satellites or spacecraft, even the smallest flaw can lead to catastrophic failure. Owens Industries machines precision aerospace components built to meet and exceed strict tolerances.

Call on Owens for parts other shops can’t produce. From prototype to production, we deliver ultra-precise components for NASA, Boeing, Lockheed Martin, Intel and other leading aerospace companies. Our team brings the experience, equipment and commitment needed to machine mission-critical parts with confidence.

What is Aerospace

CNC Machining?

Aerospace CNC machining is the creation of parts used in assembling and maintaining rockets, satellites, aircraft and space shuttles. CNC-machined components, kits and assemblies are often necessary for aircraft in the aerospace industry. Owens uses high-quality materials, including Titanium, Kovar and more, to manufacture custom aerospace parts with lasting performance.

Owens’ Aerospace Expertise

Our engineers exceed industry standards with advanced machining solutions for aerospace. Whether you need 5-axis CNC machining, micromachining, plunge/sink EDM or additive manufacturing, Owens delivers precision components built to exacting tolerances.

When other machine shops say no, Owens takes the call. We work closely with your team to produce high-accuracy parts made from challenging materials. Backed by decades of experience and the industry’s best equipment, we solve complex machining challenges others can’t.

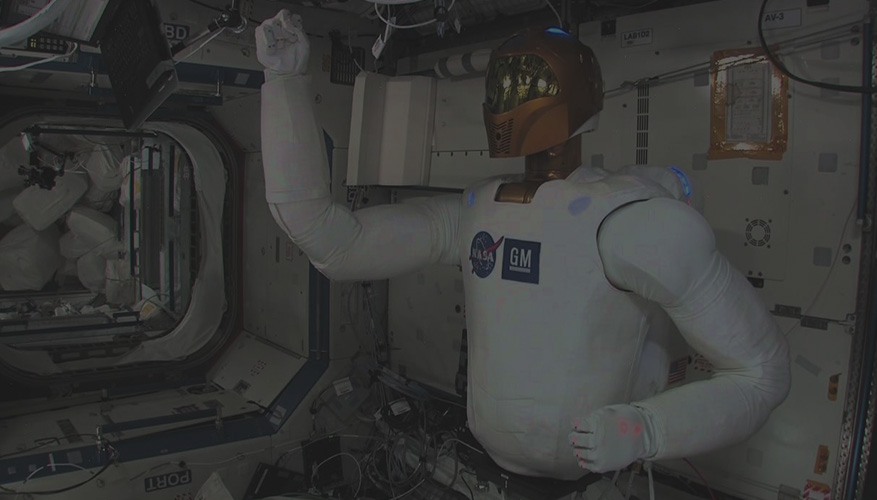

NASA & GM Partner with Owens for Aerospace CNC Machining Services

The Robonaut, a robot arm designed in partnership by NASA and GM, required a bicep assembly part. This was a unique request since this robot arm would have to be fully functional while working on the moon.

There was no room for errors in this part’s machining. This robot arm would have to fit perfectly with other parts once assembled, offering the mobility required for uses, construction and exploratory tasks deemed unsafe and/or unrealistic for humans. Owens’ machinists designed and created a fully functional bicep assembly part to the exact NASA required specifications. NASA was so pleased with our work, they commissioned two more bicep assemblies.

Robotic Bicep Assembly

Get a 360-degree view of this part and learn more about its development.

NASA Robonaut Project

Learn more about NASA’s space-savvy robotic assistant.

Work with Owens

Contact our aerospace machine shop today to discuss your component designs.

Materials

Aerospace Parts Manufacturing Process

Our CNC engineers machine aerospace parts used in fuel systems, thrusters, radar systems, satellites and other high-performance environments. From computer chassis housings built to withstand spaceflight to fluid control and turbine connectors, we deliver components with the precision required for mission-critical systems.

Every aerospace part we produce starts with high-integrity materials. Owens selects only top-grade metals and alloys trusted across aerospace programs. Below is a breakdown of the materials we work with to support advanced aerospace manufacturing.

- Alloy Steel

- Aluminum

- Brass

- Copper

- Hastelloy

- Bronze

- Hardened Steel

- Carbon Steel

Alloy Steel

Alloy steels include additional elements beyond carbon, which improve their hardness, toughness, and resistance to fatigue and wear. These steels are widely used in construction, automotive, and machinery due to their enhanced properties.

| Alloy Steel | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 4140 | 1.7225 | 708M40 | 42CrMo4 |

| 4340 | 1.6565 | 817M40 | 40NiCrMo6 |

| 8620 | 1.6523 | 805M20 | 20NiCrMo2 |

| 52100 | 1.3505 | 100Cr6 | SUJ2 |

| 4142 | 1.7227 | 708M40T | 41CrMoS4 |

| 6150 | 1.8159 | 735A51 | 50CrV4 |

Aluminum

Aluminum alloys are lightweight and strong, with excellent thermal and electrical conductivity. They are also resistant to corrosion and can be anodized for added protection, making them ideal for aerospace and packaging industries.

| Aluminum Alloy | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu |

| 6082-T651 | 3.2315 | 64430 | AlSi1MgMn |

| 6060 | 3.3206 | EN AW-6060 | AlMgSi |

| 5052 | EN AW-5052 | 3.3523 | AlMg2,5 |

| 2017A | 3.1325 | 24530 | AlCu4MgSi |

Brass

Brass is a metal known for its easy machinability and good electrical conductivity. It is ideal for applications requiring low friction, such as gears, locks, and musical instruments.

| Brass | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C36000 | UNS C36000 | CUZN39PB3 | CuZn39Pb3 |

| C46400 | UNS C46400 | CuZn38Al | Naval Brass |

| C93200 | UNS C93200 | Saems 660 | Bearing Bronze |

| C48500 | UNS C48500 | CuZn39Sn1 | Leaded Muntz Metal |

| C26000 | UNS C26000 | CUZN30 | Cartridge Brass |

| C37700 | UNS C37700 | CUZN40PB2 | Forging Brass |

Copper

Copper is excellent at conducting heat and electricity, making it perfect for electrical uses like busbars and wire connectors. It is easily recognized by its shiny reddish-orange color and is also used in plumbing and roofing.

| Copper | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C11000 | UNS C11000 | Cu-ETP | Electrolytic Tough Pitch (ETP) Copper |

| C10100 | UNS C10100 | OF-OK | Oxygen-Free Electronic (OFE) Copper |

| C10200 | UNS C10200 | OF-Cu | Oxygen-Free (OF) Copper |

| C28000 | UNS C28000 | CuZn40 | Muntz Metal |

| C14500 | UNS C14500 | TeCu | Tellurium Copper |

Hastelloy

Hastelloy is a group of nickel alloys known for their high resistance to corrosion, pitting, and stress-corrosion cracking. They are often used in harsh environments like chemical processing and aerospace, where durability is crucial.

| Hastelloy | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C276 | UNS N10276 | 2.4819 | NiMo16Cr15W |

| C22 | UNS N06022 | 2.4602 | NiCr21Mo14W |

| B-2 | UNS N10665 | 2.4617 | NiMo28 |

| X | UNS N06002 | 2.4665 | NiCr22Fe18Mo |

| C2000 | UNS N06200 | 2.4675 | NiCr23Mo16Cu |

| G-30 | UNS N06030 | 2.4603 | NiCr29Mo9Fe |

Bronze

An alloy comprised of copper and tin, it offers a wide range of properties such as high ductility, hardness, thermal conductivity, strength, and workability. Bronze is often used to manufacture nuts, bolts, threaded parts, bearings, bushings, screws, and more.

Hardened Steel

Medium or high carbon steel that has been given heat treatment to temper it, or increases the toughness of the steel. How hard the steel becomes depends on the amount of carbon present in the metal, and it’s typically used to make power shovels, nozzles, surgical instruments, and other manufactured parts.

Carbon Steel

A metal alloy of carbon and steel, but could also contain nickel, copper, or manganese. Carbon steel is commonly used for axles, gears, shafts, rails, pipelines, couplings, and more.

Get Your Aerospace Project Off the Ground

Trust our industry-leading capabilities in precision CNC milling, micromachining, EDM, Lathe work and more for small parts critical to getting large aerospace projects off the ground. We work with respected names throughout the aerospace industry, including HEICO, SNC, JPL, AMTEK, Honeywell and Parker. Contact our aerospace manufacturing company today for precision-fabricated components.

Aerospace Machining Tolerances & Capabilities

| Machining Service | 5-Axis Machining | EDM Machining | Mill-Turn Machining | CNC Lathes/Turning | Metal 3D Printed Parts |

|---|---|---|---|---|---|

| Maximum Part size | 28" x 24" x 15" | 13.5" x 21.5" | 14" dia x 16" oal | 10" dia x 10" oal | 28" x 24" x 15" |

| Standard Lead Time | 12 weeks | 12 weeks | 12 weeks | 10 weeks | 12 weeks |

| General Tolerances | .001" | .0005" | .0025" | .0025" | .001" |

| Precision Tolerances | .0001" | .00005" | .0005" | .00025" | .0001" |

| Minimum Feature Size | 250 x .250 x .250 | .01 x .01 x .01 | .060" dia x .050" oal | .060" dia x .050" oal | .250 x .250 x .250 |

| Minimum Surface Finish | 8 | 8 | 8 | 8 | 8 |

| Standard Surface Finish | 64 | 32 | 32 | 32 | 32 |

*Standard delivery is dependent on workloads. Call Owens for current lead times.

CNC Machining for the Aerospace Industry

The CNC experts at Owens Industries manufacture parts used in aerospace applications with precise specifications and high-quality materials. We excel in crafting aerospace components for a diverse range of applications, including rockets, satellites, fuel systems and turbo thrusters, leveraging the state-of-the-art CNC machines in our Wisconsin facility. Manufacturing OEM aerospace parts demands ultra-tight tolerances and advanced precision equipment. Owens Industries delivers both with unmatched expertise.

Our machining capabilities allow our CNC experts to manufacture the most precise parts at the lowest possible cost. From wire and sinker EDM to precision micromachining, the professionals at Owens Industries can produce technologically advanced aerospace components with tailored specifications.

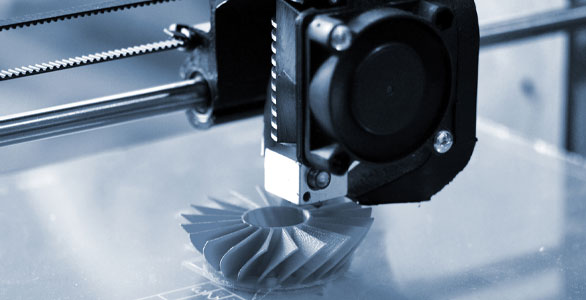

Precision Metal 3D Printed Parts for Aerospace Applications

Owens Industries uses advanced additive manufacturing to produce 3D-printed metal parts with tight tolerances and complex geometries. Our printed components meet the demands of aerospace propulsion systems, satellite assemblies and lightweight structural applications.

We work with high-performance alloys like rhenium, Inconel and cobalt-rhenium to deliver aerospace components built for extreme conditions. Every project runs through our AS9100- and ITAR-certified facility, with full post-processing and multi-axis machining for production-ready results.

Precision Machine Shop Produces OEM Parts for Astronautic Engineering Firms

As the aerospace industry continues to grow, aeronautical engineers are developing commercial, military and private aircraft capable of flying higher and faster. At the same time, astronautic engineers are pushing for greater precision in spacecraft and satellite components, driving increased demand for ultra-precise machined parts. Manufacturers rely on OEM parts built to the tightest tolerances to support complex subsystems in satellite platforms, propulsion systems and structural spacecraft components.

Since 1944, Owens Industries has advanced alongside the aerospace sector. Our temperature- and contaminant-controlled CNC facility produces high-end OEM components for the most demanding aerospace applications. Aerospace never stops moving forward, and neither do we. No matter the complexity, our skilled team has the tools and experience to get it done.

Out of this World Accuracy: 5-Axis and Wire EDM Machined Aerospace Parts

Exploring the universe takes big ideas and precise measurements. Owens Industries delivers both with ultra-accurate CNC milling and micromachining for micron-level positional control. Whether you're machining a valve housing for a hydrogen propulsion system, a microwave housing component or a titanium spline for an airflow meter or fuel system, Owens provides unmatched capability and reliability.

Our 5-axis systems and wire EDM processes achieve accuracies of ±0.05 µm and .0015" corner radii, giving aerospace manufacturers the edge in ultra-precision performance.

CNC Shop for U.S. Aerospace Companies

Top aerospace firms like SSL, Boeing, Airbus, Raytheon, General Dynamics and Ball Aerospace depend on high-precision machined parts. Few shops match the level of expertise, equipment and engineering talent Owens brings to each project.

From Atlas and Ariane rockets to the Dream Chaser Cargo System, AsiaSat 8 and SpaceX Dragon, today’s aerospace systems require parts once thought impossible to machine. Owens Industries helps push the boundaries of what’s achievable, delivering what seems unthinkable on Earth to help aerospace companies achieve the unimaginable in space.

Components We Build for the Aerospace Industry

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Valve Seat | Air Flow Regulator | Mill/Turn | 347 Stainless Steel | Diameters held within 0.0005" Concentricities |

| Control Valve Housing | Aircraft Brake | 4-Axis Milling | 2024-T351 Aluminum | MIL-Spec Ports and Internal Features |

| Check Valve | Brake Fluid Flow Control | Precision Turning | 18-8 Stainless Steel Cond B | 32 Microfinish on all Surfaces |

| Piston | Engine Valve | Conventional CNC Turning | 7075-T651 Aluminum | Maintaining Class 1 Diameter Fit Tolerance |

| Hinge, Convergent Flap | Flap Control | 3-Axis Milling | Inconel 718 | Deep Groove Milling |

| Housing, Aileron | Flap Control | 5-Axis Milling | 15-5PH Cond H1025 | Machining Finned Housing from Solid Billet Stock |

| Battery Core | Safety Equipment | Swiss Screw Machine | 6061-T6 Aluminum | Black Anodized Sleeve |

| Machined Reflector | Wing Lights | 5 Axis Profile Milling | 6061-T6 Aluminum | Milling and Polishing 16 Reflective Pockets |

| Cylinder Assembly | Flow Channel for Booster Rocket | Turning with Ceramic Inserts | A286 Alloy | Deep Drilling Through Interrupted Surfaces |

| Thruster Body | Satellite Propulsion | Precision EDM | 6Al-4v Grade 5 Titanium | EDM Nozzle Micro Taper Vectored Thru-Hole |

| DM Cover | Satellite Component | Mill/Turn | 6061-T651 Aluminum | Turn, Mill, and Drill Flanged Cover |

| Grid Clamp | Satellite Component | CNC Turn | AISI 304 Stainless Steel | Turn 0.044" Thick Ring |

Contact Owens today for ultra-precision aerospace components made to your specifications.

Cutting-Edge CNC Machines for Ultra-Precision Components

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

View our Success Gallery to see our work!