Brass

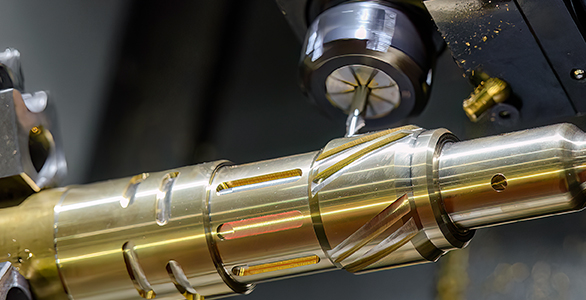

Precision CNC Brass Machining Services for Complex Components

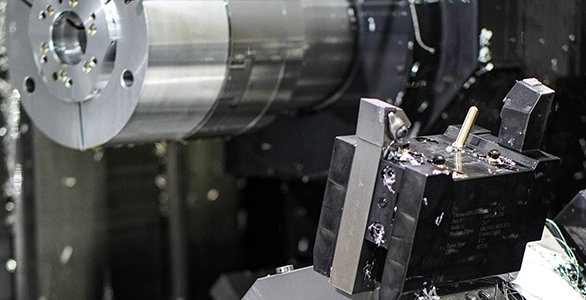

Owens Industries is a trusted name when it comes to providing advanced brass machining services. With CNC technology and state-of-the-art equipment, we can perform complex machining operations for many different CNC machining materials including brass. Our advanced machining capabilities include 4-axis and 5-axis milling, swiss machining, and even micromachining. This allows us to create the highest precision parts with the tightest tolerances. We can achieve tolerances as tight as 0.0005".

Owens Industries is a Wisconsin-based CNC machine shop, but we have been known nationally since 1944 for being on time, within budget, and within tolerance. We understand that each project is unique, which is why we offer custom brass machining services tailored to meet specific customer requirements. Our expertise in providing high-quality custom brass parts manufacturing and fabrication services is unmatched. Owens' commitment to quality assurance and inspection ensures that every precision brass CNC machining service we provide is of the highest standard.

Owens Industries

Brass Machining Services For Your Industry

Since 1944, designers and engineers have trusted Owens Industries to machine their components and parts from materials such as brass. Owens Industries utilizes advanced CNC technology and machining equipment to offer ultra-precision brass machining services. Our brass machining capabilities enable us to machine brass parts with tight tolerances and complex geometries, making us the go-to partner for various industries.

Owens Industries Precision Machined Brass Components

Owens Industries has a long storied history of being able to deliver on time and within ultra-precision tolerances. Our precision brass machining services include the machining of various components such as bolts, nuts, casings for electrical components, and more. We use advanced machining techniques to achieve tight tolerance and precision in every part we machine. It doesn't matter if you are located near our Wisconsin-based CNC machining facility or not, we serve several different industries all across America in all 50 states.

To see more of our work, please visit our CNC product image gallery and our CNC product video gallery.

Here is an example list of brass components that can be machined:

- Mechanical components, such as gears, fittings, and valves

- Electrical components, such as connectors, terminals, and switch components

- Decorative components, such as door handles, fixtures, and ornaments

- Musical instruments, such as trumpet parts, saxophone components, and trombone components

- Marine components, such as propeller components and fittings

- Plumbing components, such as faucets, valves, and fittings

- Automotive components, such as radiator components and fittings

Brass Grades For CNC Machining

| Series | Common Alloys | Main Alloying Element | Composition Range | Melting Point | Properties | Typical Applications |

|---|---|---|---|---|---|---|

| 200 | C23000, C26000, C26800 | Copper-Zinc | 90-95% Cu, 5-10% Zn | ~905°C (1661°F) | High copper content, excellent corrosion resistance, good electrical conductivity, ductility, formability | Plumbing, electronics, radiator cores, coins, medals, decor |

| 300 | C31400, C34500, C35300 | Copper-Zinc | 87-90% Cu, 10-13% Zn | ~902°C (1656°F) | Deep red color, ductility, ease of cold working, suitable for intricate designs | Applications requiring excellent formability |

| 400 | C46400, C48500, C51000 | Copper-Zinc | 85-89% Cu, 11-15% Zn | ~905°C (1661°F) | Excellent ductility, strength, corrosion resistance, golden yellow color, balanced formability and strength | Various applications requiring formability and strength |

| 500 | C54400, C52100, C54400 | Copper-Zinc | 60-63% Cu, 37-40% Zn | ~910°C (1670°F) | High corrosion resistance, excellent formability, balanced strength and ductility | Components exposed to corrosive environments |

| 600 | C62300, C67800, C64200 | Copper-Zinc | 68-71% Cu, 29-32% Zn | ~905°C (1661°F) | Excellent ductility, strength, corrosion resistance, golden yellow color, balanced formability, strength, and color | Applications requiring a balance of formability, strength, and color |

| 700 | C70600, C71500, C72200 | Copper-Zinc | 60-66% Cu, 34-40% Zn | ~920°C (1688°F) | Good ductility, strength, corrosion resistance, suitable for yellowish-gold color | Components requiring a yellowish-gold color |

| 800 | C83450, C83600, C83800 | Copper-Zinc | 74-78% Cu, 22-26% Zn | ~900°C (1652°F) | Excellent ductility, moderate strength, corrosion resistance, suitable for golden-yellow color | Applications requiring a balance of formability, strength, and corrosion resistance |

| 900 | C90300, C90500, C90700 | Copper-Zinc | 55-63% Cu, 37-45% Zn | ~940°C (1724°F) | Balance between strength and ductility, good corrosion resistance, good machinability | Fasteners, plumbing fittings, automotive components, electrical connectors |

| Leaded | C35300, C36000, C37700 | Copper-Zinc with Lead | Varies with alloy | Varies | High machinability, corrosion resistance, good strength, excellent corrosion resistance due to lead content | Intricate and complex parts through machining processes |

Brass CNC Services and Capabilities

Happy with our service? Leave us a 5-star review!