Oil & Gas

Durable Oil and Gas Component Manufacturing for Unexpected Situations

The oil and gas industry depends on complex parts built to withstand unpredictable demands. As a trusted oil and gas parts manufacturer, Owens Industries machines components to the tightest tolerances for high-performance systems. Professionals from companies like HALLIBURTON and Parker partner with us for CNC parts built with precision and consistency.

Most of our clients become lifetime partners after just one project. Our CNC machinists work directly with you to create finished components built for accuracy and reliability. We engineer every detail to fit your broader system goals and deliver consistent results for even the most challenging jobs. Contact our machine shop today for a quote on oil and gas component manufacturing.

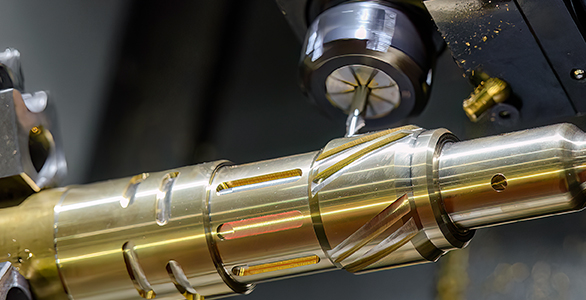

Custom Components for Oil Fire Suppression Systems

Owens Industries machines custom flappers and flapper valves designed for oil fire suppression systems. Precision components help protect expensive equipment and prevent safety failures in high-pressure environments. When accuracy matters most, our team delivers CNC components built to the highest standards for form and function.

Our oil and gas machine shop also manufactures oil and gas parts for pressure control, pumping assemblies and oilfield systems. Whether the job calls for 5-axis milling, EDM or micromachining, we work from your designs to deliver fully finished oil and gas components made for tight tolerances and long-term performance.

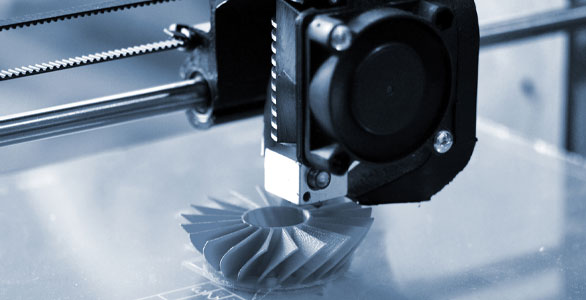

Additive Manufacturing for Oil & Gas Components

Oil and gas systems often demand intricate components with fast turnarounds and minimal waste. Additive manufacturing helps meet those demands by producing complex geometries difficult to machine with traditional methods. Owens Industries uses additive manufacturing to support oil and gas parts printing where weight reduction, rapid prototyping or internal passage features are critical.

Our parts printing capabilities complement our core CNC processes, offering added flexibility in part design and production. Partner with Owens Industries to integrate additive manufacturing into your next oil and gas project.

Precision Parts for Critical Oil & Gas Systems

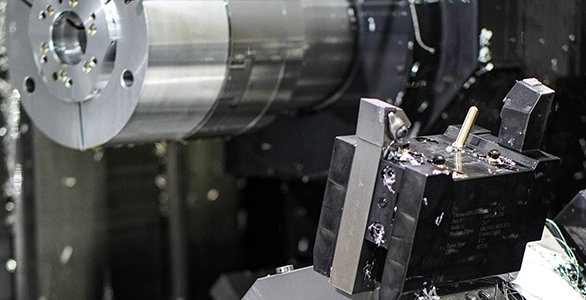

Owens Industries machines high-precision components used across the oil and gas sector. Our team manufactures custom oil and gas parts for fluid regulation, pressure systems, drive assemblies and safety equipment with tolerances down to the micron level. From concept to completion, we help engineers solve difficult challenges with parts built for performance in critical conditions.

We routinely machine precision parts for oil and gas systems requiring advanced geometries and high material integrity, including:

- Flow control housings

- Transmission sleeves and caps

- Threaded seals and bushings

- Bearing races and valve mounts

- Flappers, retainers and spring pins

We manufacture oil and gas parts using advanced techniques like mill-turn machining, EDM and lathe turning to meet exact specifications.

Materials for Oil & Gas Applications

| Material | Description |

|---|---|

| Stainless Steel and Hardened Steel: | Trusted for durability, wear resistance and tight-sealing surfaces |

| Inconel and Hastelloy: | Built to handle high-pressure, high-heat environments without degradation |

| 17-4 PH, 13CR-L80 and M50 VIM-VAR: | Selected for shaft control parts, bearing surfaces and threaded assemblies |

| Titanium and Aluminum Alloys: | Lightweight yet strong, ideal for sealing elements and housings |

| Stellite, Haynes and Monel: | Used where metal-to-metal contact or extreme conditions demand stable performance |

As a leading oil and gas parts manufacturer, Owens Industries machines precision components from advanced alloys built to perform under pressure. Each material is selected based on the demands of the part, whether for sealing, wear resistance, or performance in extreme environments.

We also machine specialty alloys, including brass, bronze, carbon steel and nickel-based materials for precise oilfield applications.

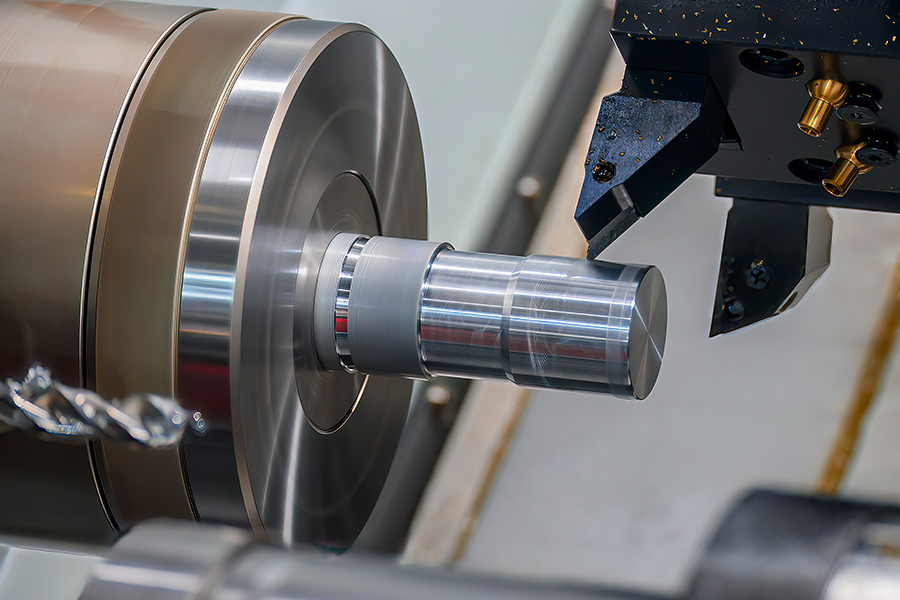

Why Choose Owens for Oil & Gas Precision Machining?

Owens Industries manufactures CNC oil and gas parts few other shops can produce. Every component is machined in a temperature-controlled facility using advanced 5-axis, EDM and micromachining equipment. As a top oil and gas parts manufacturer, we hold an ISO 9001:2015 certification and routinely machine to tolerances as tight as ±0.0001 inches.

Our team includes machinists with decades of experience, many of whom started at Owens as apprentices and have remained part of the team for over 20 years. Their knowledge and consistency shape every part we produce. From early prototypes to repeat production, we support oil and gas clients with reliable communication, high-quality work and precision oil and gas parts built to perform. Contact Owens Industries today for more information on oil and gas component manufacturing.

Components We Manufacture for the Oil & Gas Industry

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Insert | Ball Bearing Flow | 5-Axis Milling | 17-4 PH Stainless Cond H950 | (6) S-Shaped Pockets on Internal Profile |

| Control Race | Internal Drive Component | Turning and OD Grinding | M50 Vim-Var IAW AMS 6491 | Grind OD Ball Screw and Broach Internal Spline |

| Inlet Cover | Pressure Flow Cover | 5-Axis Milling | 13CR-L80 80 KISI MYS | Milled Cage Features |

| Communication Component | Pressure Regulation | Precision Turning | Inconel 625 113 Min KSI Yield | Acquiring Polished Finish with Turn |

| Equalizing Plunger | Pressure Valve | Precision Turning | Stellite 6B | 0.0004" OD Tolerance on Cobalt Alloy Part |

| Inner Race | Replaceable Bearing Track | Hard Diamond Turning | M50 Vim-Var IAW AMS 6491 | 8 Micro Finish on Race Profile |

| Torsion Spring Pin Retainer | Retention Cap | EDM Wire | 13CR-L80 NACE MR0175 | EDM Wire Curved Profile |

| Nut, Inner Race | Shaft Control | EDM Sinker | M50 Vim-Var IAW AMS 6491 | Sink Internal Ball Screw Thread |

| Hoop Constraint | Shaft Control Cap | Precision Turning | 4330 V Mod Steel 40-44 HRc | Holding 0.0002" Tolerance for Nickel Plating |

| Hex Stop | Shaft Control Component | EDM Wire | 4330 V MOD Steel | Matched Sets of Hexagon Rings |

| Control Sleeve | Shaft Control Sleeve | Hard Milling | AISI E4340 H Steel | Milling of Internal Ball Screw |

| Radial Bearing Housing | Shaft Control Unit | 5-Axis Milling | 17-4 ph Cond H950 | Deep Feature 5-Axis Milling |

| Bearing Housing | Shaft Coupling Device | 5-Axis Milling | 13CR-L80 80 KSI MYS | Intricate Internal Ports |

| Ball Joint Housing | Transmission Control | Hard Milling | AISI 8620 Carburized 58-62 HRc | Hard Milling 0.375" Scallops |

| Ball Lock | Transmission Control | 5-Axis Milling | AISI 4330 V Mod 115 Min KSI Yield | Milling Eccentric Lobe |

| Static Dog Lock | Transmission Control | Diamond Turning | Lescalloy M50 VIM-VAR | Gear Cutting |

| Equalizing Flapper | Valve Cover | 5-Axis Milling | 718 Inconel NACE MR0175 120 KSI MYS | Milled Saddle-Shaped Profile |

| Flapper Mount | Valve Head | 5-Axis Milling | Inconel 925 105 Min KSI Yield | Milling Saddle Profile |

| Soft Seat | Well Head Seal | 5-axis milling | 30% Carbon Filled Teflon | Saddle shaped stepped profile seal ring |

| Soft Seat Retaining Ring | Well Head Seal Retainer | 5-Axis Milling | 13CR-L80 | Milling Saddle Profile |

| Lens Cell | Flow Viewing Port | Mill/Turn | 6061-T6 Aluminum | Turn 2.075-32 ID Thread |

| Gas-Fluid Manifold Block | Fluid Control | 4-Axis Milling | 6061-T6 Aluminum | Drill and tap (8) NPT Threaded Holes |

| Cylinder Block | Gas Flow Manifold | 5-Axis Milling | 6061-T6 Aluminum | Machine 12 Micro Finish Surfaces for Press Fit Bushings |

| Solenoid Valve Seat | Hydraulic Piston Seat | Hard Turning | 431 Stainless Steel per BS970 | Ballize Seal Seat to 0.078" Profile |

Contact our CNC machine shop today for precision oil and gas part manufacturing nationwide.

View our Success Gallery to see our work!