Equipment

High-Tech Zeiss QCI Equipment at Owens Industries

Owens Industries uses Zeiss quality control inspection equipment to maintain the highest precision in every component we produce. Known for their advanced metrology capabilities, Zeiss machines deliver unmatched accuracy and reliability across aerospace, automotive and medical applications. Owens Industries utilizes Zeiss technology and other top brands for consistent, high-quality results in every part. Contact us today to learn more about our Zeiss inspection equipment and capabilities.

Our ZEISS CNC Machines

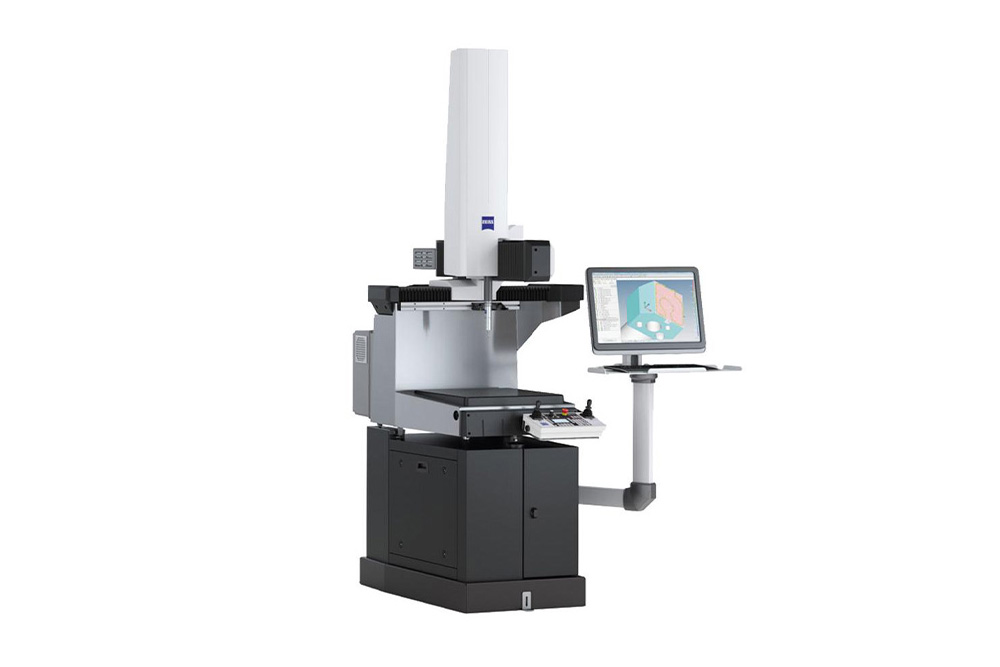

Zeiss DuraMax Scanning CMM

The Zeiss DuraMax Scanning CMM is a high-precision coordinate measuring machine, adding advanced metrology capabilities to Owens Industries' quality control processes. Designed for accuracy and reliability, the DuraMax is ideal for inspecting complex aerospace, automotive and medical manufacturing parts. With its robust construction, high-speed scanning and user-friendly software, the DuraMax guarantees Owens Industries maintains the highest standards of quality and precision in every component.

Dimensions

- Measuring Volume: 19.69 x 19.69 x 19.69 in

- Machine Footprint: 26.38 x 34.25 in

Facts

- Measurement Accuracy: ±0.00012 in

- Scanning Speed: Up to 20.47 in/s

- Probe Type: Multi-sensor capable (optical and tactile)

- Software: ZEISS CALYPSO for advanced measurement and analysis

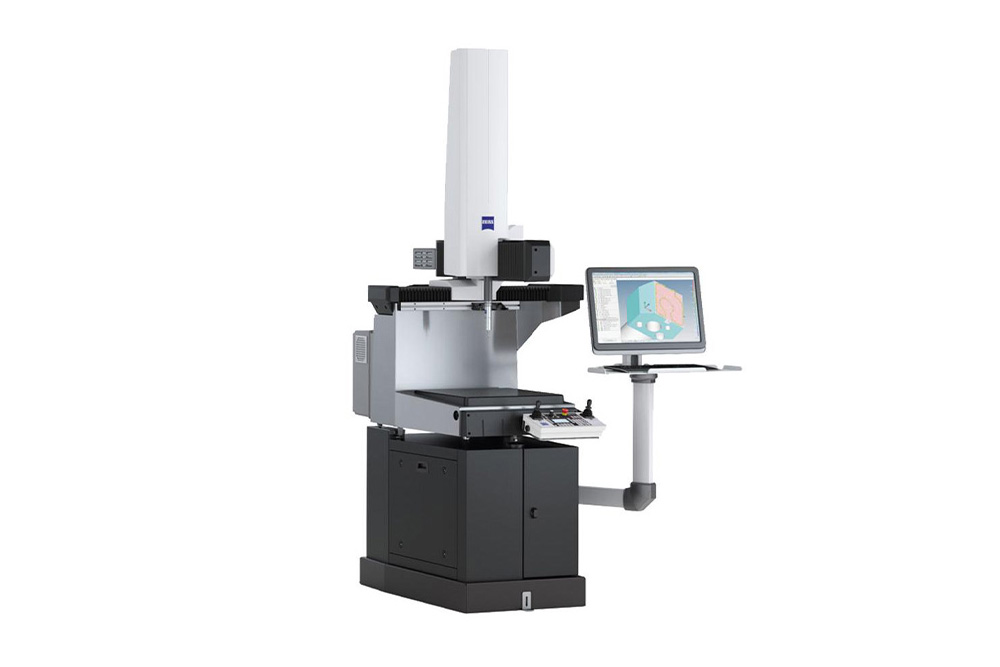

Zeiss O-Inspect 3/2/2 Multi-Sensor CMM

The O-Inspect 3/2/2 Multi-Sensor CMM is a versatile inspection system, combining optical and tactile measurement technologies to enhance Owens Industries' quality control capabilities. The O-Inspect 3/2/2 is designed for precision and efficiency while inspecting complex automotive, medical and electronics parts. Multi-sensor functionality, high-speed scanning and advanced software help Owens Industries deliver components with unmatched accuracy and reliability.

Dimensions

- Measuring Volume: 11.81 x 7.87 x 7.87 in

- Machine Footprint: 34.06 x 39.37 in

Facts

- Measurement Accuracy: ±0.00016 in

- Scanning Speed: Up to 17.13 in/s

- Probe Type: Multi-sensor (optical, tactile and line scan)

- Software: ZEISS O-INSPECT for comprehensive measurement and analysis

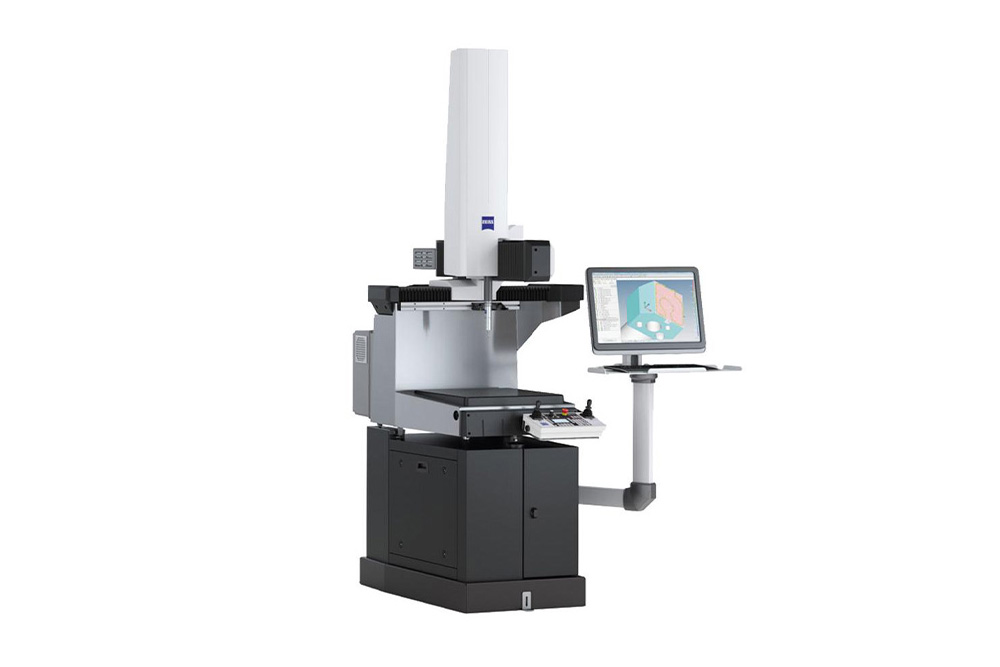

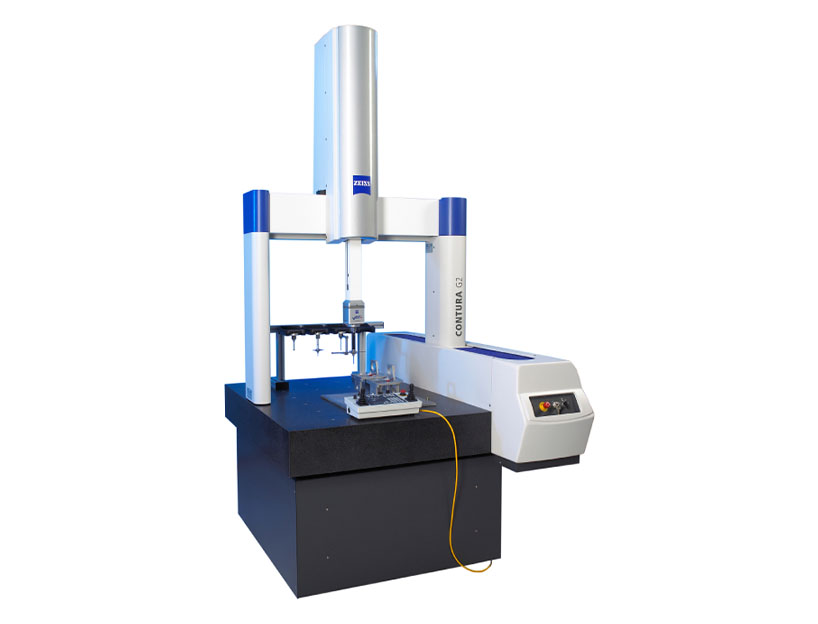

Contura G2 Direkt (2011)

The Contura G2 Direkt (2011) is a high-performance coordinate measuring machine, offering precision and reliability for Owens Industries' quality control processes. The G2 Direkt is ideal for inspecting medium to large parts with tactile measurement, ideal for aerospace, automotive and energy components. The Contura G2 Direkt guarantees accuracy and efficiency across components with its robust construction, direct drive technology and advanced software.

Dimensions

- Measuring Volume: 27.56 x 27.56 x 23.622 in

- Machine Footprint: 56.29 x 60.04 in

Facts

- Measurement Accuracy: ±0.00012 in

- Scanning Speed: Up to 19.69 in/s

- Probe Type: Tactile (single and multi-point)

- Software: ZEISS CALYPSO for advanced measurement and analysis

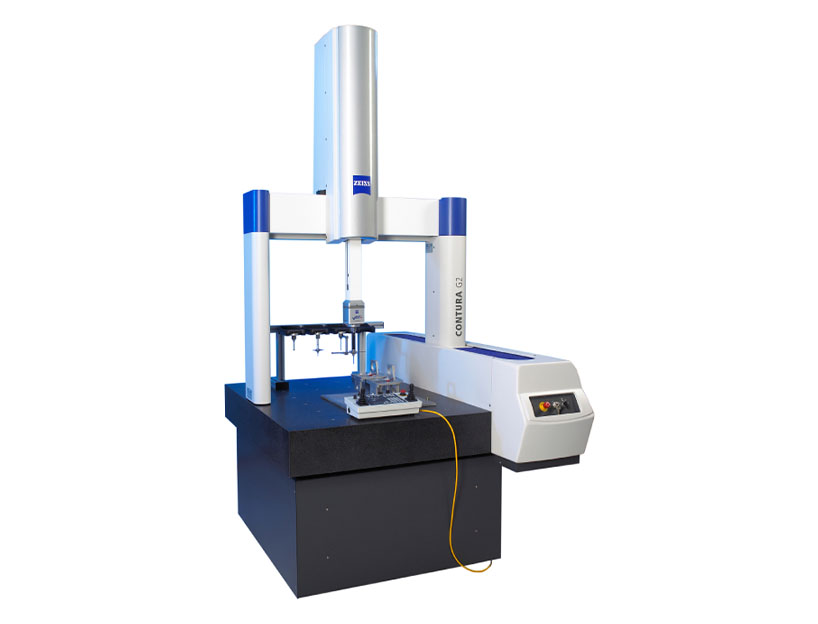

Zeiss Contura (2022)

The Contura (2022) is a high-precision coordinate measuring machine offering advanced metrology capabilities for Owens Industries' quality control processes. Designed for tactile measurement, the Contura is best for inspecting medium to large aerospace and automotive parts. Robust construction, high-speed scanning and advanced software make the Contura (2022) ideal for maintaining accuracy and efficiency.

Dimensions

- Measuring Volume: 35.43 x 70.86 x 31.49 in

- Machine Footprint: 59.06 x 47.24 in

Facts

- Measurement Accuracy: ±0.00012 in

- Scanning Speed: Up to 19.69 in/s

- Probe Type: Tactile (single and multi-point)

- Software: ZEISS CALYPSO for advanced measurement and analysis

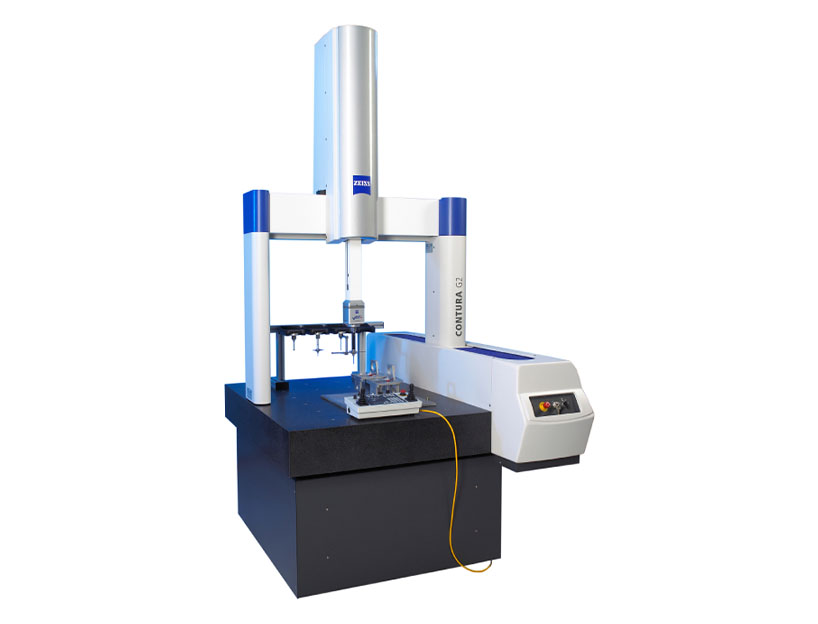

Contura w/ Line Scan (2022)

The Contura w/ Line Scan (2022) is a state-of-the-art coordinate measuring machine combining tactile and optical measurement technologies to enhance Owens Industries' inspection capabilities. Designed for precision and versatility, this CMM is ideal for inspecting complex aerospace, automotive and medical manufacturing parts. With its line scan sensor, high-speed scanning, and advanced software, the Contura w/ Line Scan helps Owens Industries deliver components with exceptional accuracy and quality.

Dimensions

- Measuring Volume: 35.43 x 70.86 x 31.49 in

- Machine Footprint: 59.06 x 47.24 in

Facts

- Measurement Accuracy: ±0.00012 in

- Scanning Speed: Up to 19.69 in/s

- Probe Type: Multi-sensor (tactile and line scan)

- Software: ZEISS CALYPSO for comprehensive measurement and analysis

Happy with our service? Leave us a 5-star review!