Metal Printed Parts

Complex Metal Parts for Aerospace & Defense

Owens Industries manufactures quality printed parts with unmatched precision. As a specialized metal 3D printed parts company, we excel at engineering parts with tight tolerances, complex geometries and challenging materials. Every project supports performance under pressure, from aerospace propulsion systems to next-generation defense platforms.

Our team works with clients nationwide to deliver functional components made from materials like Inconel, nickel alloys, rhenium, cobalt-rhenium and molybdenum, 3D printed to tolerances as tight as ±0.0001". Owens produces parts others avoid, including cobalt-rhenium thrusters, rhenium optical housings and nickel gimbals. Contact us today for a quote.

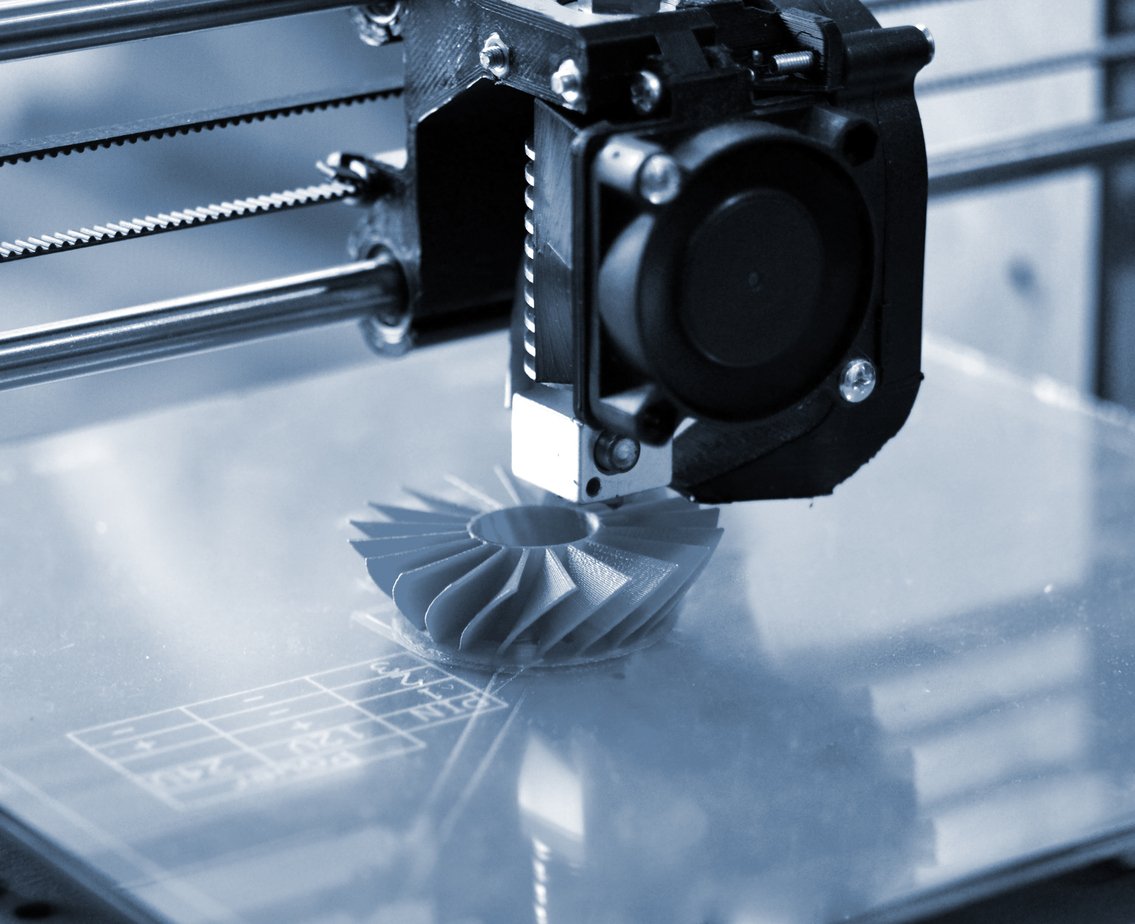

What is Metal 3D Printing?

Metal 3D printing is an additive manufacturing process that produces parts by printing them layer by layer from a digital model. This process offers advantages over traditional subtractive methods like CNC machining, which removes material from a solid block. Metal 3D printing forms parts directly from the build material to reduce waste and enables more intricate shapes.

Metal 3D printing supports designs impossible or cost-prohibitive with traditional manufacturing. Printed parts can include internal channels, fine latticework and geometries made for performance, not just machinability. Owens Industries uses additive manufacturing to produce parts from high-performance materials like rhenium, cobalt-rhenium, Inconel and molybdenum, each selected for durability in high-stress environments.

Metal 3D Printing Benefits Over Traditional CNC Machining

- Design Freedom: Print internal features, organic shapes and parts resistant to traditional machining methods.

- Reduced Waste: Build parts with only the material needed—no excess stock, no chip removal.

- Faster Prototyping & Development: Speed up development cycles and reduce lead times for high-value parts.

- Weight Reduction: Create lighter parts without losing strength, especially for aerospace and defense systems.

- Cost Efficiency: Produce short-run parts without setup costs tied to custom tooling.

Why Choose Owens Industries for Metal 3D-Printed Parts?

Owens Industries partners with engineers and OEMs in California, Texas, Florida, New Jersey, Massachusetts, Illinois, Minnesota and beyond to print parts no one else will take on. As a trusted metal printed parts service, we specialize in projects rejected by other shops due to extreme complexity, exotic materials or ultra-tight tolerances. From rhenium optical housings to cobalt-rhenium thrusters, we deliver functional parts for real-world use, not just prototypes.

Every project takes place at our AS9100 & ITAR-Certified facility, where printed parts go through post-processing, multi-axis machining and detailed inspections. We work with high-strength alloys, corrosion-resistant materials and geometries built for performance under pressure. If you’re working on a critical component and need a partner who can print to a tolerance of 0.0001", Owens should be your next call.

Minimum project value begins at $25,000. If we’re not the right fit, we’ll help connect you with someone who is. Request a quote today.

View our Success Gallery to see our work!

Metal 3D Printed Parts Applications in Aerospace & Defense

Complex Rocket Parts

Metal 3D parts printing opens new possibilities for high-performance engine components. Printed Inconel nozzles and cobalt-rhenium combustion liners support faster design cycles, reduced weight and optimized flow characteristics.

Lightweight Aircraft Components

Metal 3D printing produces lightweight parts, improving fuel economy and structural performance. Printed air ducts, brackets and internal supports reduce mass without compromising strength.

End-Use Parts for Unmanned Aerial Systems (UAS)

UAS platforms benefit from printed housings, heat shields and internal supports built to match evolving mission specs. Owens produces flight-ready parts from nickel alloys, aluminum and rhenium blends.

Custom Tooling Solutions

Printed jigs, fixtures and gauges improve assembly accuracy while cutting lead times. Owens uses additive manufacturing to produce one-off tooling for aerospace and defense teams needing repeatable precision in tight timeframes.

Rapid Prototyping for Defense Applications

When speed matters, we deliver fully functional prototypes in less time. Metal 3D printed parts give defense teams a way to test, refine and deploy solutions faster without waiting on tooling.

Maintenance, Repair & Operations (MRO)

When original suppliers fall short, Owens’ 3D metal parts printing fills the gap. We reverse-engineer and produce legacy components from exotic alloys like cobalt-rhenium to reduce lead times and system downtime.

Materials

Printed Parts Material Capabilities

Owens Industries has extensive experience manufacturing 3D metal printed parts from different materials, including Hastelloy, Kovar, Molybdenum, Rhenium, Cobalt-Rhenium, Invar and more.

- Stainless Steel

- Aluminum

- Inconel

- Titanium

- Hastelloy

- Invar

- Kovar

- Molybdenum

- Rhenium

- Cobalt-Rhenium

Stainless Steel

Stainless steel is known for its strength, heat, and corrosion resistance, along with its durability and attractive appearance. These qualities make it suitable for a wide range of uses, including kitchenware, medical instruments, and construction.

| Stainless Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 316L | UNS S31603 | X2CrNiMo17-12-2 | Stainless Steel 316L |

| 304 | UNS S30400 | X5CrNi18-10 | Stainless Steel 304 |

| 17-4 PH | UNS S17400 | X5CrNiCuNb16-4 | Stainless Steel 17-4 PH |

| 303 | UNS S30300 | X8CrNiS18-9 | Stainless Steel 303 |

| 420 | UNS S42000 | X20Cr13 | Stainless Steel 420 |

| 440C | UNS S44004 | X105CrMo17 | Stainless Steel 440C |

Aluminum

Aluminum alloys are lightweight and strong, with excellent thermal and electrical conductivity. They are also resistant to corrosion and can be anodized for added protection, making them ideal for aerospace and packaging industries.

| Aluminum Alloy | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu |

| 6082-T651 | 3.2315 | 64430 | AlSi1MgMn |

| 6060 | 3.3206 | EN AW-6060 | AlMgSi |

| 5052 | EN AW-5052 | 3.3523 | AlMg2,5 |

| 2017A | 3.1325 | 24530 | AlCu4MgSi |

Inconel

Inconel is a strong, corrosion-resistant nickel alloy, ideal for challenging aerospace applications. It can withstand extreme temperatures and pressures, making it suitable for jet engines and gas turbines.

| Inconel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 718 | UNS N07718 | 2.4668 | NiCr19Fe19Nb5Mo3 |

| 625 | UNS N06625 | 2.4856 | NiCr22Mo9Nb |

| 600 | UNS N06600 | 2.4816 | NiCr15Fe |

| X-750 | UNS N07750 | 2.4669 | NiCr15Fe7TiAl |

| 601 | UNS N06601 | 2.4851 | NiCr23Fe |

| 725 | UNS N07725 | 2.4668 | NiCr19Fe19Nb5Mo3 |

Titanium

Titanium is a lightweight metal with excellent strength, low thermal expansion, and high corrosion resistance. Its ability to be sterilized and its biocompatibility make it unique, especially in medical implants and aerospace components.

| Titanium Grade | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 5 (Ti-6Al-4V) | UNS R56400 | 3.7165 | Ti-6Al-4V |

| 2 | UNS R50400 | 3.7035 | CP Titanium |

| 23 (Ti-6Al-4V ELI) | UNS R56401 | 3.7165 | Ti-6Al-4V ELI |

| 9 (Ti-3Al-2.5V) | UNS R56320 | 3.7195 | Ti-3Al-2.5V |

| 7 (Ti-0.2Pd) | UNS R52400 | 3.7235 | Ti-0.2Pd |

| 12 (Ti-0.3Mo-0.8Ni) | UNS R53400 | 3.7105 | Ti-0.3Mo-0.8Ni |

Hastelloy

Hastelloy is a group of nickel alloys known for their high resistance to corrosion, pitting, and stress-corrosion cracking. They are often used in harsh environments like chemical processing and aerospace, where durability is crucial.

| Hastelloy | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C276 | UNS N10276 | 2.4819 | NiMo16Cr15W |

| C22 | UNS N06022 | 2.4602 | NiCr21Mo14W |

| B-2 | UNS N10665 | 2.4617 | NiMo28 |

| X | UNS N06002 | 2.4665 | NiCr22Fe18Mo |

| C2000 | UNS N06200 | 2.4675 | NiCr23Mo16Cu |

| G-30 | UNS N06030 | 2.4603 | NiCr29Mo9Fe |

Invar

Invar is a nickel alloy with very low thermal expansion, making it highly stable and perfect for precision applications such as instrumentation and aerostructure molds. It is also used in scientific instruments where dimensional stability is critical.

| Invar | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 36 | UNS K93600 | 1.3912 | FeNi36 |

| 42 | UNS K94200 | 1.3917 | FeNi42 |

| 48 | UNS K94800 | 1.3922 | FeNi48 |

| 32-5 | UNS K94610 | 1.3911 | FeNi32-5 |

| 42-6 | UNS K94620 | 1.3913 | FeNi42-6 |

| 46 | UNS K94630 | 1.3914 | FeNi46 |

Kovar

Kovar is known for its exceptional thermal stability and precise expansion properties, along with its strength and compatibility with glass-to-metal sealing. These qualities make it ideal for specialized applications in electronics, aerospace, and medical devices.

Molybdenum

Molybdenum is known for its high-temperature strength, thermal conductivity, and resistance to corrosion in harsh environments. These qualities make it invaluable for aerospace components, electronic devices, and power generation equipment.

Rhenium

Rhenium is commonly used to manufacture parts for high-temperature environments like thrusters, thermocouplers and electrical contacts, and is used in aerospace, electronics, power generation and more.

Cobalt-Rhenium

Cobalt-rhenium alloys provide unmatched durability in high-temperature, corrosive environments. Owens Industries machines complex cobalt-rhenium components for aerospace, energy and surgical applications requiring extreme performance.

Tolerances

Owens Industries' Metal Printed Parts Tolerances

Owens Industries’ precision metal 3D printing achieves tolerances as tight as ±0.0001 inches—ideal for high-performance parts with intricate geometries and multiple built-in features. With a maximum part size of 28” x 24” x 15” and a standard lead time of 12 weeks, we produce complex components with exceptional consistency, tight tolerances and a flawless finish in every build.

| Attribute | Value |

|---|---|

| Maximum Part Size | 28" x 24" x 15" |

| Standard Lead Time | 12 weeks |

| General Tolerances | .001" |

| Precision Tolerances | .0001" |

| Minimum Feature Size | .250 x .250 x .250 |

| Minimum Surface Finish | 8 |

| Standard Surface Finish | 32 |

*Standard delivery dependent on workloads. Call Owens for current lead times.

Industries

3D Metal Printed Parts Industries

Owens Industries supports engineers, OEMs and manufacturers working in sectors where failure is not an option. Our printed parts serve demanding applications in aerospace, defense, energy and beyond. Whether you need corrosion-resistant tooling, high-temperature housings or precision flight components, we deliver parts built to perform under pressure.

FAQ

Metal Printed Parts FAQs

How long does it take to produce a metal 3D printed part?

Production time depends on part size, geometry and material. Simple 3D printed parts may take a few hours, while larger or more complex builds with post-processing may take several days. Additive manufacturing allows faster turnaround than traditional methods for many parts.

Which industries benefit most from additive manufacturing?

Aerospace, defense, energy and medical sectors rely on 3D printed parts made from advanced alloys. Additive manufacturing supports lightweight designs, short-run production and complex geometries without long lead times.

Does additive manufacturing replace CNC machining?

Not entirely. While metal 3D printing excels at building complex shapes, most parts still require CNC machining to meet surface or tolerance specs. Owens combines additive manufacturing with 5-axis milling and EDM for production-ready results.

What happens after a part is 3D printed?

Most parts go through post-processing steps like heat treatment, machining or surface finishing. Owens manages all finishing operations in-house to maintain dimensional control and quality throughout.

How precise are metal 3D printed parts?

Additive manufacturing provides good baseline accuracy. For high-precision applications, Owens uses secondary machining to achieve tolerances as tight as ±0.0001".