Aluminum

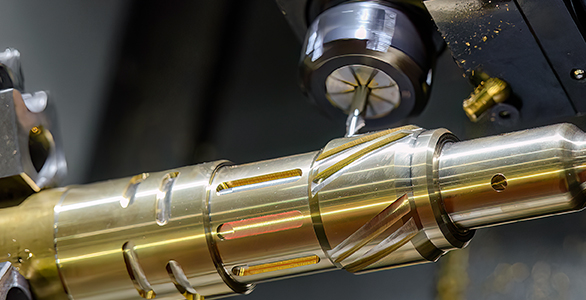

Precision CNC Aluminum Machining Services for Complex Components

Owens Industries is a trusted name when it comes to providing advanced aluminum machining services. With CNC technology and state-of-the-art equipment, we can perform complex machining operations for many different CNC machining materials including aluminum. Our advanced machining capabilities include 4-axis and 5-axis milling, swiss machining, and even micromachining. This allows us to create the highest precision parts with the tightest tolerances. We can achieve tolerances as tight as 0.0005".

Owens Industries is a Wisconsin-based CNC machine shop, but we have been known nationally since 1944 for being on time, within budget, and within tolerance. We understand that each project is unique, which is why we offer custom aluminum machining services tailored to meet specific customer requirements. Our expertise in providing high-quality custom aluminum parts manufacturing and fabrication services is unmatched. Owens' commitment to quality assurance and inspection ensures that every precision aluminum CNC machining service we provide is of the highest standard.

Owens Industries

Aluminum Machining Services For Your Industry

Since 1944, designers and engineers have trusted Owens Industries to machine their components and parts from materials such as aluminum. Owens Industries utilizes advanced CNC technology and machining equipment to offer ultra-precision aluminum machining services. Our aluminum machining capabilities enable us to machine aluminum parts with tight tolerances and complex geometries, making us the go-to partner for various industries. We serve these industries:

Owens Industries Precision Machined Aluminum Components

Owens Industries has a long storied history of being able to deliver on time and within ultra-precision tolerances. Our precision aluminum machining services include the machining of various components such as cores, housings, brackets, stators, rotors, and other manufactured products. We use advanced machining techniques to achieve tight tolerance and precision in every part we machine. It doesn't matter if you are located near our Wisconsin-based CNC machining facility or not, we serve several different industries all across America in all 50 states.

To see more of our work, please visit our CNC product image gallery and our CNC product video gallery.

Aluminum components for CNC Machining

| Part | Application | Industry | Machining Process Used | Specific Feature |

|---|---|---|---|---|

| Control Valve Housing | Aircraft Brake | Aerospace | 4-Axis Milling | MIL Spec Ports and Internal Features |

| Swivel Bracket | Aerospace | Aircraft OEM | 4-Axis Milling | 3 Piece Assembly |

| Support Assembly | Aerospace | Aircraft OEM | 5-Axis Milling | Aluminum Tube with Formed Welded Bracket |

| Stator | Blood Gas Analyzer | Medical | 3-Axis Milling | Circle Interpolate Boss with 0.0005" Tolerance |

| Rotor | Blood Gas Analyzer | Medical | 4-Axis Milling | 0.010" Thick Cell Walls |

| Rotor Housing | Blood Gas Analyzer | Medical | 4-Axis Milling | Micro Milling of Housing to Accept Electronics |

| Gas-Fluid Manifold Block | Fluid Control | Natural Gas Industry | 4-Axis Milling | Drill and tap (8) NPT Threaded Holes |

| Machined Reflector | Wing Lights | Aerospace | 5-Axis Profile Milling | Milling and Polishing 16 Reflective Pockets |

| Optics Block | Laser Alignment Tool | Research and Development | 5-Axis Machining | Hole Alignment Tolerance 0.001mm |

| Valve Housing | Titan Rocket | Rocket Engine Component | 5-Axis Machining | 5-Axis Milling of Cylindrical Elbow Housing |

| Cylinder Block | Gas Flow Manifold | Natural Gas Industry | 5-Axis Milling | Machine 12 Micro Finish Surfaces for Press Fit Bushings |

| Lens Cell | Flow Viewing Port | Natural Gas Industry | Mill/Turn | Turn 2.075-32 ID Thread |

| Battery Core | Safety Equipment | Aerospace | Swiss Screw Machine | Black Anodized Sleeve |

| DM Cover | Satellite Component | Space Research | Mill/Turn | Turn, Mill and Drill Flanged Cover |

| Paddle | Actuator Arm | Military | 4-Axis Machining | Milling 0.020" Thick Webs with 0.002" Flatness |

| Piston | Engine Valve | Aerospace | Conventional CNC Turning | Maintaining Class 1 Diameter Fit Tolerance |

Aluminum Grades For CNC Machining

The above information is a general overview, and specific grades within each series may have variations in alloying elements and characteristics. Please refer to the detailed specifications of individual Aluminum grades for more accurate information.Interested in utilizing aluminum for your machined component? Contact Owens Industries today.

| Series | Main Alloying Element | Cost | Machinability | Weldability | Properties | Typical Applications |

|---|---|---|---|---|---|---|

| 1000 | 99% Aluminum | Low | Excellent | Not recommended | Highly corrosion resistant, excellent workability, electrical conductivity | Chemical equipment, reflectors, food industry containers |

| 2000 | Copper | Moderate | Good | Moderate | High strength, good machinability, limited corrosion resistance | Aircraft structures, rivets, truck wheels, screw machine products |

| 3000 | Manganese | Moderate | Excellent | Moderate | Good workability, moderate strength, excellent corrosion resistance | Cookware, automotive trim, roofing, siding |

| 4000 | Silicon | Moderate | Good | Not recommended | Good flow characteristics, lower melting point | Brazing alloys, welding wires |

| 5000 | Magnesium | Moderate | Good | Good | Good corrosion resistance, moderate-to-high strength, good weldability | Marine applications, tankers, structural applications, pressure vessels |

| 6000 | Magnesium & Silicon | Moderate | Good | Good | Medium strength, good corrosion resistance, good formability, weldability | Architectural extrusions, frames, railings, automotive parts |

| 7000 | Zinc | High | Fair | Moderate | Very high strength, less corrosion resistance than 2000 series | Aircraft structures, sporting equipment, automotive parts |

Aluminum CNC Services and Capabilities

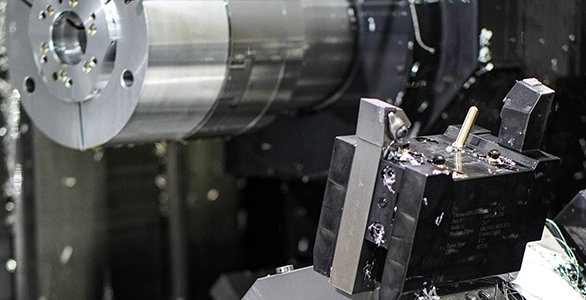

Cutting Edge CNC Machines for Ultra-Precision Components

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

HERMLE 5-axis CNC machining centers for complex, multi-axis components

HERMLE 5-axis CNC machining centers for complex, multi-axis components  Agie Charmilles wire EDM systems for intricate features and fine surface finishes

Agie Charmilles wire EDM systems for intricate features and fine surface finishes  Zeiss inspection equipment for advanced quality control and dimensional verification

Zeiss inspection equipment for advanced quality control and dimensional verification  DMG MORI CNC milling and turning machines for precision production and complex geometries

DMG MORI CNC milling and turning machines for precision production and complex geometries Happy with our service? Leave us a 5-star review!