Industries Served

Wisconsin Machine Shop Provides Industries with Ultra-Precision Machining

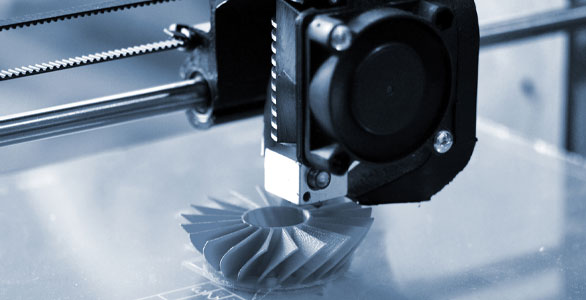

Owens Industries provides the highest quality CNC machining services to industries US-wide. We have vast experience producing complex components requiring tight tolerances, high precision, and extraordinary accuracy for major industries like aerospace, additive manufacturing, and more. When other CNC machine shops turn away – claiming your requests impossible to achieve – count on Owens. We face challenges head-on, conquering them with the same tight precision. Every time.

Our machining services include the highest levels of 5-axis work, Wire EDM, EDM machining, micromachining, CNC lathe machining, and more. Call upon us to produce the problem parts you need to move your project forward.

Aerospace

Aerospace

For a flawless application, aircraft and aerospace parts demand the highest precision and exacting accuracies. Depend on Owens to deliver components meeting or exceeding your quality standards.

Learn more

Military / Defense

Military / Defense

Owens not only provides unmatched 5-axis milling, wire EDM, and lathe services, but we keep the specifics of your components completely confidential, ensuring vital secrets are not leaked.

Learn more

Medical

Medical

Medical manufacturers and innovators alike choose Owens when they need to outsource CNC services, create prototypes, or simply cut costs while improving product quality.

Learn more

Oil & Gas

Oil & Gas

When you need complex components for your oil & gas or energy applications, turn to Owens Industries. From micromachining to 5-axis milling, we can meet your every CNC need.

Learn more

Food Manufacturing

Food Manufacturing

Food processing plants comply with a number of health codes and industry standards, often requiring parts of their equipment to be machined with specific materials and precision; Owens is capable of meeting your exact needs.

Learn more

Aircraft

Aircraft

Our CNC professionals are capable of machining a multitude of aircraft components, and to the exact precision required when adhering to the highest industry standards.

Learn more

Optics

Optics

Microscopes, telescopes, cameras, and more requiring 100% accuracy on machined components will get nothing less than expected when Owens is on the job.

Learn more

Pharmaceutical

Pharmaceutical

CNC machining for the pharmaceutical industry involves the precision manufacturing of critical components and equipment used in drug production and medical devices.

Learn more

Energy

Energy

Owens Industries offers custom CNC machining services for the energy industry, delivering precision-engineered components made from high-quality materials like titanium and Hastelloy.

Learn more

All Industries

Custom Precision Machining Services For Every Industry

No matter which industry you’re in, we’ll machine custom parts and complex components to keep your operations strong and orders filled on time. Owens Industries’ skilled CNC machinists work closely with you to custom-engineer the highest quality components that fit your specific project needs. Across all industries including Food, Pharmaceutical, and Energy, you can count on us for the best precision parts made with the tightest tolerances.

Our machinists provide precision machining services that are capable of meeting your industry's needs.

CNC Machining Services for the Aircraft and Aerospace Industry

When small parts are instrumental to getting big Aerospace or Aircraft projects off the ground, you can count on Owens Industries. Founded in 1944, Owens has considerable experience in the CNC machining of components for the Aerospace Industry.

From anti-locking brake housings for jets to a bicep assembly of a robotic arm for the Mars project, we have machined a multitude of complex components and parts for our Aerospace and Aircraft clients.

Aerospace materials We Make

We work extensively with many different Aerospace materials, including:

- Stainless Steel

- Inconel

- High Purity Aluminum

- Super Conducting, Very High Purity Copper **

- Kovar

- Invar

- Titanium

** (untouchable by human hands – we use white gloves for handling this copper)

If you are looking for a reliable manufacturer for micron tolerance ultra-precision components, performing CNC machine work, Fine Wire EDM, and Plunge/Sink EDM with exacting tolerances – call on the expertise of Owens Industries, LLC.

View our Success Gallery to see our work!

Optical Industry

CNC Machining Services

Benefiting the Optical Industry

Components and parts machined for the Optical Industry require the highest precision and accuracy to ensure they can be easily placed in complex equipment, such as microscopes, lasers, and telescopes. Owens specializes in the machining of intricate parts for electron microscopes – including the screen holder for electron microscope lenses as well as the upper lens body. We have the CNC machines required to meet the tight tolerance demands of Optical Industry products, as well as the experience to understand the end use of the parts we are machining and how they are expected to perform—allowing our machinists to determine the best way to effectively machine the part so it fits perfectly into its assembly.

Trusted By the Military & Defense Industries for Quality and Discretion

Since 1944, Organizations in the Military and Defense Industry frequently have been choosing Owens Industries as their go-to CNC Machine Shop. As the technology evolved, so did Owens. Not only do we have the capabilities to meet extremely tight tolerances with the highest precision and accuracy, but we also have the discretion to keep our clients and their top-secret projects confidential. Each of our employees, vendors, and facility visitors sign confidentiality agreements, agreeing to keep the contents and workings of our facility within the facility walls. We have machined complex parts for certain defense agencies without knowing what the component would be specifically used for. Still, we always meet the challenge with unbelievable precision and continue to serve every client’s needs.

Achieving the Impossible for the Oil & Gas Industry

A multitude of organizations within the Oil & Gas and Energy Industry count on Owens for high-end ultra-precision machine work. Most of our clients use our services once and become lifetime partners when they see the results our machines and people produce. We frequently machine flat and curved flappers – as well as the housing on which flappers sit– for oil suppression systems. We have also machined complex components used to pump the sludge out of the bottom of unpressurized oil wells for our clients. Contact our 5-axis and EDM machinists today to discuss the manufacturability of your designs.

Ultra Precision Machine Work for the Medical Industry

When small parts are instrumental to the success of lifesaving advances in health care technologies, call on Owens Industries. We have been a critical component supplier to the CT and MRI Scanner Systems, as well as a manufacturer of surgical instruments, including Trocar/Cannula systems, biopsy cutters, and more. In addition to CT, MRI components, and surgical instruments, we manufacture various medical components such as Respiratory, Cardio Pulmonary, and Cardiac Devices.

Examples of our CNC machining work for the medical industry include Collimators for CT scanners, MRI table components, Anodes for X-Ray systems, miniature components and gears for Cardiac Devices, Insertion Equipment used in DNA analysis, implantable medical device components, and 5 axis machining of titanium implants for orthopedic use. We manufactured a micron toleranced impeller for VAD – Ventricular Assist Device – VAD, commonly known as the heart pump.

Precision CNC Manufacturing from a Reliable Company

If you’re looking for high-quality precision parts from a CNC shop you can trust, make sure to give Owens Industries a call. We’ve been providing ultra-precision CNC machining for over 70 years, and are dedicated to offering our clients the absolute best in multi-axis milling and electrical discharge machining. We’d love to discuss your products and build you a quote; give us a call today!

Our precision machining capabilities include:

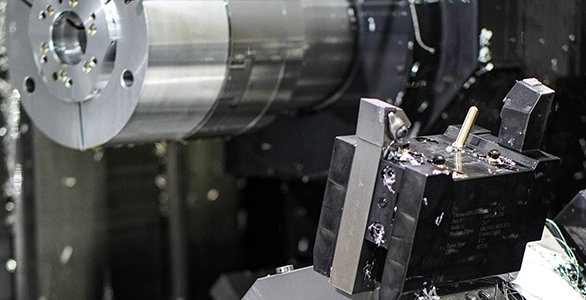

- Wire EDM - a very detailed process that entails using a thin wire as an electrode to cut a material (workpiece) with sparks. This process produces an extremely accurate cut and quality finish, even on the smallest of products.

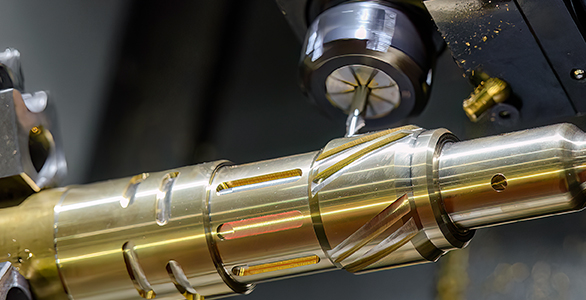

- 5 Axis Milling - this CNC process is unique in its ability to effectively process part sizes and shapes with essentially infinite possibilities. Rotating and cutting parts on 5 axes, the final product is clean and extremely precise.

- Lathe & Turning - this operation is one of the most basic machining processes; the part is rotated while a single point cutting tool is moved parallel to the axis of rotation. Turning can be done on the external surface of the part as well as internally (boring).

- Micromachining - refers to the precise milling and manufacturing of extremely small parts and products. These components can be cut down to one-thousandth of a millimeter, helping make the production of micron parts more efficient and realistic.

Contact our CNC Machinists for more information on our services and how they can meet your industry-specific needs.

Happy with our service? Leave us a 5-star review!