Aircraft

Complex Aircraft Parts

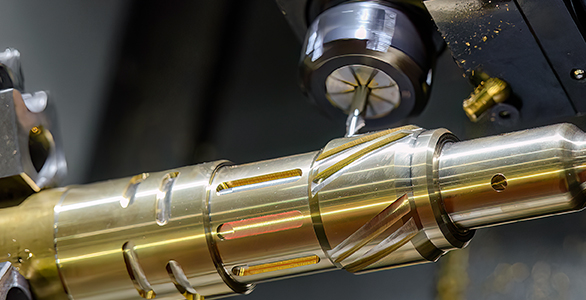

Machined to the Highest Standards

Owens Industries is the leader in aircraft CNC machining. As air travel builds and expands, aircraft fleets consistently need the best parts to maintain efficient, reliable operation and safety. Precision and accuracy are of the utmost importance when machining components for civil aviation and military aviation needs. We work closely with you to develop the specific aircraft components and spare parts your project requires.

Whether you require ribs, spars or frames for airframe structures, struts, beams or actuators for landing gear, or flaps and ailerons for control surfaces, Owens Industries machines every component you need to extreme precision.

Have problem parts or impossible aircraft components? In a hurry? Call upon Owens' expertise. Our top-of-the-line 5-axis and Wire EDM machines allow for faster, more accurate construction of aircraft parts. Owens' fast turnaround times, coupled with consistent accuracy, make production of even the most precision-dependent components a breeze.

Precision Aircraft Components Manufactured with Attention to Detail and Safety

Our rigorous tests and extensive safety protocols reveal any component flaws before installation. At Owens Industries, we construct parts and components to your exact specifications. Our Wire EDM process allows us to achieve perfection with our CNC-machined parts.

Whether you need an aluminum anti-locking brake housing for an aircraft or any other complex aircraft component, our CNC machining services will exceed your expectations while meeting the highest industry standards. We create custom components from scratch and replicate specific parts with ease. Our micromachining processes create incredibly small, precise pieces, with resolutions up to 0.1 microns. We achieve your designs no matter the size or tolerance requirements.

With our ultra-precise CNC machines, your aircraft will be more efficient and affordable than ever. We create customizable parts best fit for your aircraft designs. Our 5-axis machines allow for multiple part components to be made simultaneously, saving you time and money.

Superior Machined Components for Aircraft and Jet Applications

Our engineers develop custom components for your business, guaranteeing consistency among designs and construction. No matter how complex, Owens Industries will work with you to meet your precise requirements. Ask us about our expertise with:

- Bushings, hinges, brackets and clamps

- Connectors, housings and control panels

- Engine casings, fan discs, engine mounts and combustion chambers

- Fuselage frames, braking components and winglets

For unparalleled CNC machine work, Wire EDM and Ram/Plunge/Sink EDM with exacting tolerances for airplanes, jets, helicopters or any other aircraft / military machine, rely on the expertise of Owens Industries, LLC Our engineers are ready to make your designs take flight today.

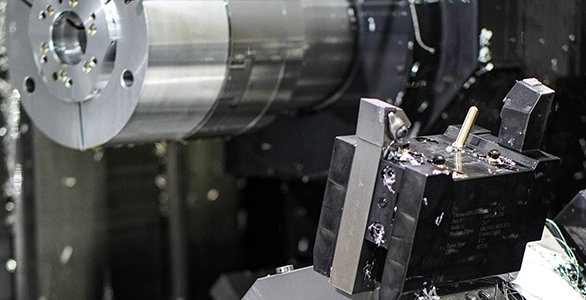

The Most Precise Components Made with CNC Lathes

We manufacture precision components for the aircraft industry with our high-quality CNC lathes. Our professionals understand the aviation industry has a constant high demand for the latest and best in hi-tech precise components, and our lathes provide the very best in aviation parts made with the highest quality materials and the tightest tolerances.

Thanks to our ISO 9001:2015 certified standards, we manufacture our components for the aviation industry with the highest quality materials at the lowest prices. Our CNC machining process is fast, and its automated cycle time makes it ideal for high production applications for aircraft, jets and aviation machines.

CNC Machining Services For the Aviation Industry

Some of the aircraft CNC machining services offered by Owens Industries include:

- Electrical Discharge Machining (EDM)

- 5 Axis Machining

- Turning

- Milling

- Deburring

No matter what type of component you need manufactured for your aircraft application, the professionals at Owens Industries can build it for you. Our high-quality CNC machining lathes produce the most precise parts at a fraction of the cost – contact us today to learn more about our CNC capabilities.

High-Quality CNC Aircraft Parts Manufacturer

Over a century removed from the days of wood, wire and canvas bi-planes, modern aircraft enlist an ever-expanding complement of precise and complex parts in order to operate with consistent efficiency, safety and durability. The complexity of modern aircraft cannot be overstated: elaborate systems of avionics, trim systems and servo tabs, evolving hydraulic-assisted control surfaces and improved engine mechanics require precise components in order to function.

As systems evolve, they are often retrofitted into existing airframes as a necessary cost-saving measure. The average commercial jetliner is over a decade old, but with ever-changing technologies and regulations, an old Boeing 737 could expect to see an extensive list of upgrades and part replacements. A single improvement may be implemented in a range of existing structures. Thus, custom parts are often needed to ensure proper compatibility between platforms. There's no better choice than Owens Industries for custom CNC-machined parts to keep your aircraft flying smoothly.

Manufacturing Custom Precision Aircraft Components

Owens leads the way in precise machining of OEM parts for the avionics industry. Because we can produce such a wide array of custom airplane parts, you will have the exact part you need, fulfilling the precise compatibility requirements for a range of airframes.

We incorporate the latest in metal shaping, grinding, cutting and deburring techniques to create precision parts too complex for other machine shops. Some examples of our OEM aircraft parts and machining techniques include:

- Valve seat for an airflow regulator – 5-axis machined aluminum

- Machined reflectors for wing lights – 5-axis profile milled aluminum

- Aileron housing – 5-axis milled stainless steel

- Door Hatch stop – 4-axis milled titanium

- Control valve housing for brake system – 4-axis milled aluminum

- Pneumatic valve armature assembly – Lathe-milled stainless steel

- …and more

Custom-designed OEM parts crafted by the expert machinists at Owens Industries allow aircraft subsystems to integrate perfectly into either new or existing airframes, with the fastest turnaround times to perfectly meet any airplane manufacturer’s exacting quality and time requirements.

We Machine Any Airplane Part in Any Material

With commercial, recreational, military and private aircraft consisting of many millions of different parts, components and subsystems, an airplane part manufacturer must be able to produce several different parts made from a broad range of materials. Of course, maintaining the highest quality of output is essential. Owens Industries operates at unsurpassed levels of quality and precision, producing OEM aircraft parts from materials like:

Components We Build for the Aircraft Industry

Our components are trusted by the biggest names in the aircraft industry, like HEICO, Boeing, General Dynamics and Raytheon. Let us make sure your project lives up to its potential.

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Support Assembly | Aerospace | 5-Axis Milling | 5052-0 and 5052-F Aluminum | Aluminum Tube with Formed Welded Bracket |

| Swivel Bracket | Aerospace | 4-Axis Milling | 2024-T351 Aluminum | 3 Piece Assembly |

| Door Stop | Hatch Stop | 4-Axis Milling | 6Al-4v Grade 5 Titanium | Fine Milling Profiles to Accept Plating and Paint |

| Armature Assembly | Pneumatic Valve | Lathe, Mill w/ 4th axis Indexer | 430 and 303 Stainless Steel | Welded/Polished Assembly |

| Pilot End Cap | Fluid Flow | Multi-Axis Mill/Turn | 1117 CRS | Milling Radial Ports |

Cutting-Edge CNC Machines for Ultra-Precision Components

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

View our Success Gallery to see our work!