Pharmaceutical

Achieve the Impossible With the Best CNC Machines in the Industry

High-quality pharmaceutical equipment is a necessity in today’s modern medical industry. Machine manufacturers can tailor production systems down to the last detail to ensure everything is manufactured to the right standard. Pharmaceutical medical components such as centrifuges, cooling towers, and granulators must be manufactured to the highest possible standards.

Owens Industries can produce components for cardiovascular and orthopedic devices, surgical instrumentation, and implants. We work with materials ranging from titanium and stainless steel to invar, Kovar, and Inconel. Our trained professionals work alongside you from start to finish, accomplishing even the most impossible machining goals.

Have an impossible component? Call Owens. Our expertise will help you achieve a finished product that meets your exact application.

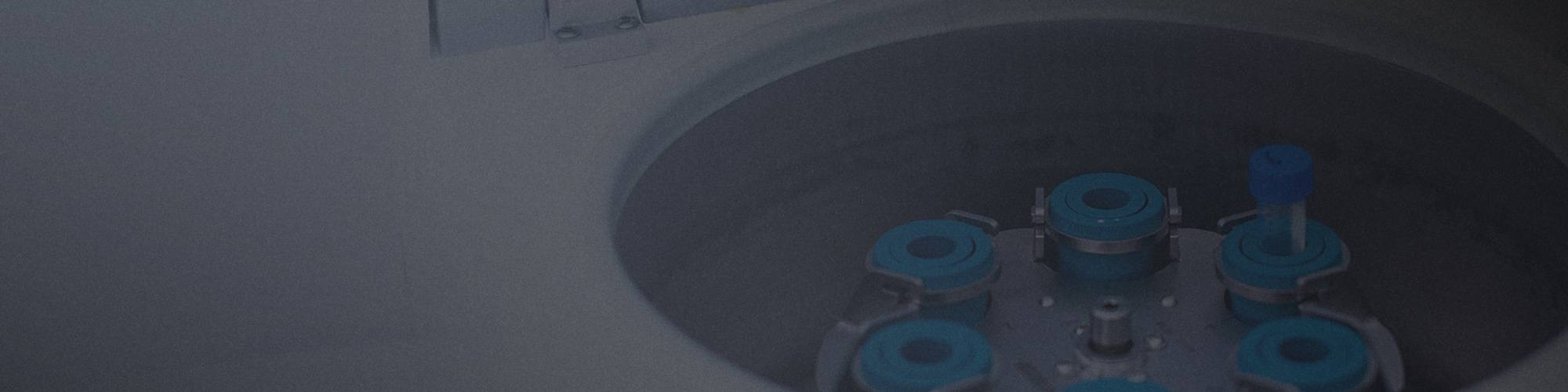

What Are Centrifuges?

A centrifuge is a common laboratory device used in the pharmaceutical industry used for separating fluids, gas, or liquid, based on density. Spinning a vessel at high speeds allows the centrifugal force to push heavier materials to the outside of the vessel.

Some of the most common types of centrifuges used by pharmaceutical companies include: Benchtop, Refrigerated Benchtop, Clinical Benchtop, Microcentrifuges, and Concentrators.

Owens Industries offers the best in CNC machining processes to fabricate high-quality centrifuges for the pharmaceutical industry. Experienced precision CNC machinists at Owens utilize the latest technology to offer a multitude of components built to near-impossible specifications.

Medical Part Manufacturing Capabilities

Owens Industries has engineered and manufactured a wide array of precise components. Our trained professionals will work alongside you from start to finish, accomplishing even the most impossible machining goals for your pharmaceutical components.

Some of the components we build for pharmaceutical companies include:

- Centrifuges

- Cooling towers

- Dryers

- Granulators

- Capsuling equipment

- Coating machines

- Inspection equipment

- And much more

We’ll surpass your expectations with our unmatched medical precision machining services, and we promise the best work with a quick turnaround time. We take medical component challenges head-on and create medical parts no one else would even bother attempting to try. Our skilled staff is able to design and work through any glitch or problem a specific component may have.

Get the Most from 5-Axis Machining

Understanding the full capabilities for 5-axis machining is the difference between an ordinary component and an extraordinary one. We have an arsenal of the best 5-axis machinery on the market produced by the best brands and are always operated by expert machinists who know how to utilize 5-axis technology for your particular components.

5-axis milling still plays a key role in certain medical, pharmaceutical, and ophthalmic applications. If you’re manufacturing medical devices, surgical instrumentation, or other related equipment, Owens can handle your 5-axis machining demands – delivering the highest precision results every time.

Components We Build for the Medical and Pharmaceutical Industries

Working with the components and machine parts for the medical and pharmaceutical industry comes down to precision and high-quality materials. Owens Industry's has proven that we can do this at the highest level, making sure your manufacturing projects stay on track and move along smoothly. We have worked with and gained the trust of industry experts like ABBOTT and EDWARDS due to the quality of the components we produce for those we work with.

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Rotor | Blood Gas Analyzer | 4-Axis Milling | 6061-T6 Aluminum | 0.010" Thick Cell Walls |

| Rotor Housing | Blood Gas Analyzer | 4-Axis Milling | 6061-T6 Aluminum | Micro Milling of Housing to Accept Electronics |

| Stator | Blood Gas Analyzer | 3-Axis milling | 6061-T6 Aluminum | Circle Interpolate Boss with 0.0005" Tolerance |

| Objective Head | Catheter Head | EDM Sinker | 17-4PH Steel | EDM Sink with Miniature Copper Electrodes |

| Barrier | CT Scanner | Conventional Turn and Mill | 718 Inconel | Used Ceramic Tooling for Turning |

| Arc, Support | CT Scanner Rail | 4-Axis Milling | Project 70 Steel | Drilling and Tapping Holes on the Face of a 48" Radius |

| Impeller | Fluid Flow | 5-Axis Milling | PEEK | Burr-Free Micro Milling |

| Micro-Tip | Instrument Cap | Micro Turning | AISI 316 Stainless Steel | Micro Wire EDM |

| Gear Plate | Laser Eye Keratome | 4-Axis Milling | 17-4 Ph Cond H900 | Mill to Accept Miniature Gears |

| Insulator, Conductivity | Element Isolator | Mill/Turn | Kel-F PCTFE Plastic | Turn Tapered ID Profiles |

| Impeller, Polished | Experimental Heart Pump | 5-Axis Milling | 6Al-4v Titanium | Burr Free Polished Impeller Surface |

| Alignment Screw | CT Scanner | Swiss Screw Machine | 718 Inconel | Burr Free Part for Clean Room Use |

| Nozzle, Dispensing | Drug Dispensing Nozzle | Hard Turning | 17-4 PH Cond H900 | EDM Wire 2mm Thru-Hole over 8 " Length |

Contact our Wisconsin CNC machinists today to discuss your design and machining needs.

Cutting-Edge CNC Machines for Ultra-Precision Components

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

View our Success Gallery to see our work!