Cobalt-Rhenium

CNC Machining Services for High-Performance Cobalt-Rhenium Alloys

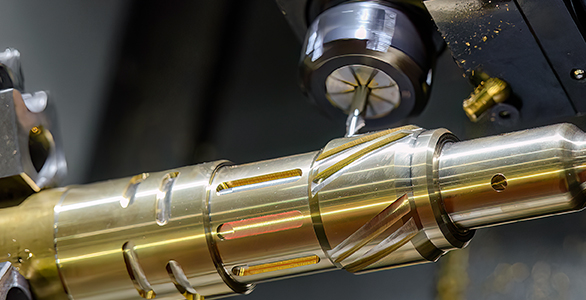

Cobalt-rhenium alloys offer extreme thermal resistance, strength retention and oxidation resistance in the most demanding operating environments. Owens Industries machines cobalt-rhenium components with advanced 5-axis milling, precision EDM and Swiss micromachining systems designed for high-performance CNC materials. Our ultra-precise CNC capabilities allow us to meet tolerance requirements as tight as 0.0005" for intricate geometries and high-temperature applications.

Owens Industries has been a trusted partner in CNC manufacturing since 1944. Our Wisconsin-based team machines specialized materials to produce precision components for aerospace, medical, defense and energy clients across the United States. Every project receives personalized attention from prototype to production run and meets strict quality and performance standards.

Owens Industries

Cobalt-Rhenium Machining Services For Your Industry

Owens Industries delivers precision cobalt-rhenium machining services tailored to complex parts used in aerospace propulsion, medical instrumentation and military systems. Cobalt-rhenium’s strength at elevated temperatures makes it ideal for mission-critical parts in high-stress applications. Our CNC experts use multi-axis machining centers, high-speed spindles and fine-tuned inspection systems to meet the rigorous demands of your application.

Owens Industries Precision Machined Cobalt-Rhenium Components

Cobalt-rhenium alloys are selected for their reliability in extreme thermal and corrosive environments. Owens Industries supports clients with tight-tolerance machining of cobalt-rhenium parts used in both experimental and production-level systems. Our Wisconsin-based CNC machining facility handles single-part prototypes and repeat production orders with equal precision.

Common components include:

- Turbine Vanes: Designed for jet engines and power generation systems operating at high heat

- Combustion Liners: Resistant to thermal shock and oxidation in aerospace propulsion

- Medical Cutting Tools: Durable, wear-resistant alloys suited for repeat sterilization cycles

- Thruster Components: Stable in vacuum and high-velocity gas flow environments

- Nozzles and Inserts: Used in high-erosion, high-pressure systems

Contact Owens to discuss your specific cobalt-rhenium component or assembly needs. To see more of our work, please visit our CNC product image gallery and our CNC product video gallery.

Cobalt-Rhenium Grades For CNC Machining

| Series | Main Alloying Element | Density (g/cm³) | Melting Point (°C) | Properties | Typical Applications |

|---|---|---|---|---|---|

| Cobalt-Rhenium Alloy | Cobalt, Rhenium | ~9.2–9.5 | ~2000+ | High-temperature strength, creep resistance, oxidation resistance | Jet engines, turbine components, medical tools, thrusters |

The above data reflect general properties of cobalt-rhenium alloys. Specific formulations may vary depending on performance requirements and manufacturing process.

Cobalt-Rhenium CNC Services and Capabilities

Cutting Edge CNC Machines for Ultra-Precision Components

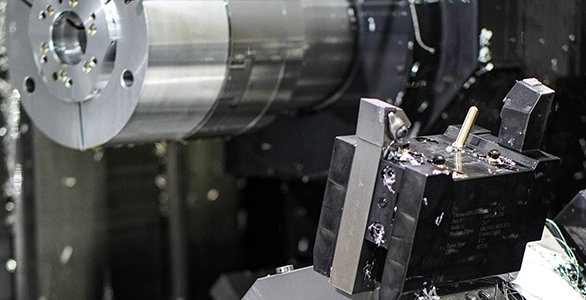

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

HERMLE 5-axis CNC machining centers for complex, multi-axis components

HERMLE 5-axis CNC machining centers for complex, multi-axis components  Agie Charmilles wire EDM systems for intricate features and fine surface finishes

Agie Charmilles wire EDM systems for intricate features and fine surface finishes  Zeiss inspection equipment for advanced quality control and dimensional verification

Zeiss inspection equipment for advanced quality control and dimensional verification  DMG MORI CNC milling and turning machines for precision production and complex geometries

DMG MORI CNC milling and turning machines for precision production and complex geometries Happy with our service? Leave us a 5-star review!