VIM VAR

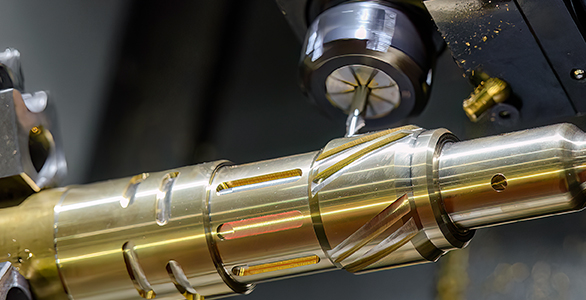

The Best CNC Machined Components Made by Owens Industries

Vim Var is the double melting process combining vacuum induction melting (VIM) and vacuum arc remelting (VAR). This process is designed to give materials a low degree of nonmetallic inclusions and soft magnetic properties after they have been heat-treated.

*Owens Industries does not sell or supply Vim Var but has the capabilities to machine it.

Owens Industries Precision Machined Tungsten Components

Vacuum Induction Melting (VIM) is the process used to melt specialty metals and high-grade steels through electromagnetic induction. Once the metal is melted, it is refined under a vacuum until the desired melt composition is where it needs to be. The VIM process is commonly used to produce the following:

- Stainless steel

- Superalloys

- Magnetic alloys

- Battery Alloys

- High-grade non-iron metals

- And much more

Vacuum Arc Remelting (VAR) is the process used to remelt a consumable electrode with an arc, continuously. During this process, a vacuum is being used at all times in order to extract impurities and to prevent the emergence of oxide. This process is used to improve the purity and quality of the materials being melted in the VIM process. Overall, this is done to improve the strength and fatigue resistance of the materials that first enter the process.

Interested in utilizing VIM VAR materials for your machined component? Contact Owens Industries today.

VIM VAR CNC Services and Capabilities

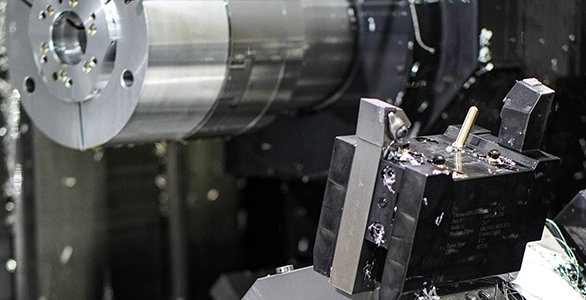

Cutting Edge CNC Machines for Ultra-Precision Components

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

HERMLE 5-axis CNC machining centers for complex, multi-axis components

HERMLE 5-axis CNC machining centers for complex, multi-axis components  Agie Charmilles wire EDM systems for intricate features and fine surface finishes

Agie Charmilles wire EDM systems for intricate features and fine surface finishes  Zeiss inspection equipment for advanced quality control and dimensional verification

Zeiss inspection equipment for advanced quality control and dimensional verification  DMG MORI CNC milling and turning machines for precision production and complex geometries

DMG MORI CNC milling and turning machines for precision production and complex geometries Happy with our service? Leave us a 5-star review!