The Medical Industry in Princeton, NJ Trusts Owens Industries

Princeton, NJ is home to many medical and pharmaceutical businesses, including Neuland Laboratories, SunGen Pharma, Eleison Pharmaceuticals, and much more. The state of New Jersey has multiple nationally ranked hospitals, and medical equipment suppliers must provide the absolute best, most reliable products to end users. Many medical devices, machines, and surgical instruments require high quality machined components to properly function.

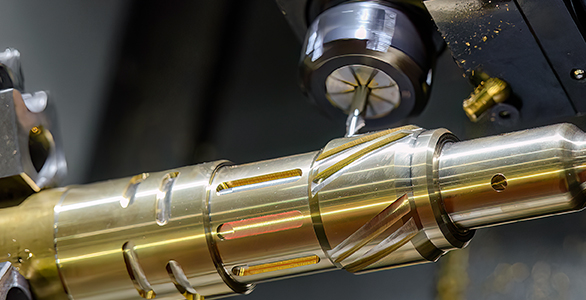

When precision it of the utmost importance to accommodate the high safety demands in the medical industry, choose Owens. Collimators for CT scanners, MRI table components, every part of a Lasik Surgery Device (excluding the motor), and much more have been expertly machined by our staff. Our CNC machinists and programmers have extensive experience designing custom components for every aspect of the medical industry. We can manufacture custom parts or handle regular productions of critical components. We strive to improve the quality of life for patients throughout the country with the highest precision machining services in the U.S.

Contact Owens Industries today to learn more about manufactured medical components.

| |

Custom Machined Components for the New Jersey Medical Industry

Owens Industries is America’s trusted supplier of medical components critical to surgical instruments, medical devices, and machines. Whether we’re engineering a Ventricle Assist Device (VAD) or a Lasik surgery blade, we ensure the highest tolerance and precision possible. Owens Industries is committed to improving the quality of life for patients and medical staff throughout the industry.

Owens Industries is the right choice for CNC machining of medical parts including:

- Surgical scissors – an essential instrument in virtually every medical procedure, when they’re not used to get into skin they are used to cut sutures. Surgical scissors are available in a number of shapes and sizes to fit the need of a wide range of applications – they are particularly small when used in eye surgeries. If you’re a surgical instrument manufacturer looking for a reliable CNC machine shop that can achieve incredible results, Owens is the answer! Stainless steel, straight, curved, flat, blunt, sharp – whatever the specifications of your scissors, we can meet your exact demands.

- Cannulas – medical products like IV cannulas are in high demand because they’re used in virtually every medical center across the world. Like many surgical instruments, they are available in multiple sizes, similar to needle gauges. We use state-of-the-art equipment like multi-axis milling and wire EDM to produce high precision cannulas that are safe and effective. The hollow metal tube and sharp, angled point of an IV cannula can be produced with exacting accuracies in our Wisconsin Machine Shop.

- Biopsy tubes – what is being biopsied determines the type of biopsy needle used during the procedure. Since not all biopsies are the same, there is no one size fits all needle for the task. We understand that safety, accuracy, and cost are all important factors when manufacturing medical tools; we help you win on all fronts with high quality, ultra-precision CNC machining services.

- Saw guides for bone surgery – helps orthopedic surgeons make the cleanest cuts possible, and protects against cutting too far into bone while sawing. Orthopedic procedures require the highest precision machined tools to produce the highest precision results. Whether you’re looking to outsource your medical machining needs permanently or require a custom saw guide for a future surgery, give us a call for a quote!

Contact the experts at Owens Industries today to get a quote on medical components.

Have problem parts or impossible components? In a hurry? Call on the expertise of Owens. Complex parts with tight deadlines are our specialty.

Cutting Edge CNC Machines for Ultra-Precision Components

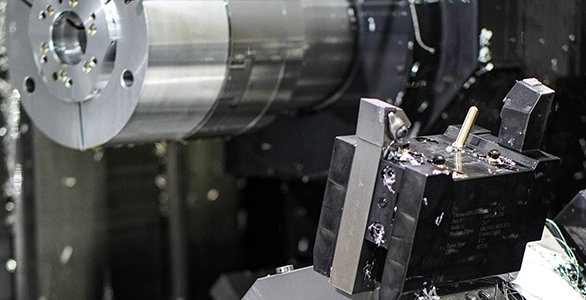

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

HERMLE 5-axis CNC machining centers for complex, multi-axis components

HERMLE 5-axis CNC machining centers for complex, multi-axis components  Agie Charmilles wire EDM systems for intricate features and fine surface finishes

Agie Charmilles wire EDM systems for intricate features and fine surface finishes  Zeiss inspection equipment for advanced quality control and dimensional verification

Zeiss inspection equipment for advanced quality control and dimensional verification  DMG MORI CNC milling and turning machines for precision production and complex geometries

DMG MORI CNC milling and turning machines for precision production and complex geometries Get high-quality manufactured CNC components made with the best materials from Owens Industries.