Micromachining Experts Achieve Exacting Results

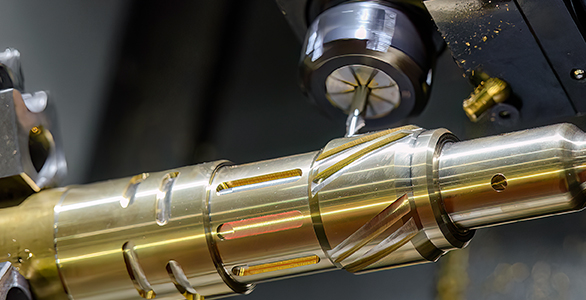

Biotechnology and Life Sciences are top industries in Lexington Kentucky, each requiring professional micromachining services to manufacturer precision components critical to the completion of innovative and lifesaving technologies and products. Owens Industries’ skilled CNC machinists provide services meeting our clients exact specifications with turnaround times meeting their needs. Our CNC machining capabilities include: 3, 4, and 5 Axis Milling; Ram, Plunge, Sinker, and Wire EDM; Lathe and Turning. Before finishing each part with a by-hand deburring process, we run several comprehensive precision tests to ensure exacting accuracies.

Biotechnology and Life Sciences are top industries in Lexington Kentucky, each requiring professional micromachining services to manufacturer precision components critical to the completion of innovative and lifesaving technologies and products. Owens Industries’ skilled CNC machinists provide services meeting our clients exact specifications with turnaround times meeting their needs. Our CNC machining capabilities include: 3, 4, and 5 Axis Milling; Ram, Plunge, Sinker, and Wire EDM; Lathe and Turning. Before finishing each part with a by-hand deburring process, we run several comprehensive precision tests to ensure exacting accuracies.

Owens has machined a variety of complex medical components, including:

- Alignment screws for CT Scanners

- Gear plates for laser eye keratomes

- Impellers

- Rotors for blood gas analyzers

If you have complex components with high demand for accuracy and precision, you want Owens on the job.

| |

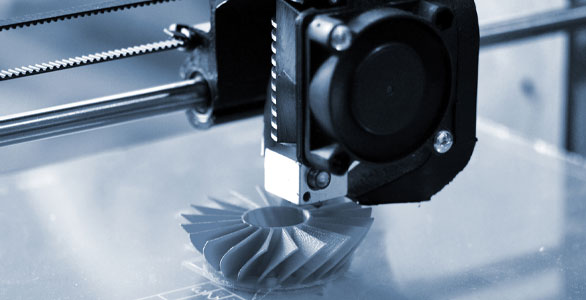

Producing Complex Components Critical To Innovative Products

Owens Industries has the best CNC machining equipment on the market, pairing state-of-the-art technology with years of dedicated skill and experience of our staff to provide ultra-precision results. Every aspect of our controlled facility is designed to perfectly machine complex components with high precision requirements. The positive airflow pressure in our Wire EDM department keeps a room temperature within +/- 0.5 degrees. This ability to maintain exact temperatures within a room is critical during machining processes. Dust and particles within the air are also controlled by using Electrostatic and Ion Filtration systems. To achieve the impossible, it takes an immaculate facility and CNC machinists and programmers who dedicate themselves to creating products of absolute perfection.

Contact our CNC precision machinists to learn more about our facility or to discuss the manufacturability of your design.

Have problem parts or impossible components? In a hurry? Call on the expertise of Owens. Complex parts with tight deadlines are our specialty.

Cutting Edge CNC Machines for Ultra-Precision Components

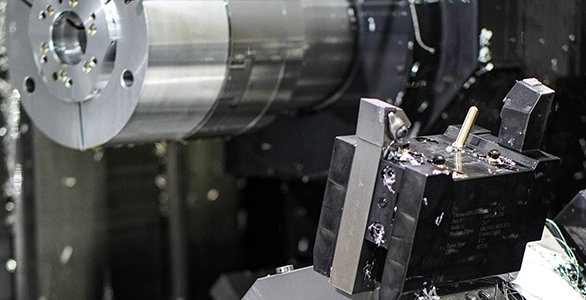

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

HERMLE 5-axis CNC machining centers for complex, multi-axis components

HERMLE 5-axis CNC machining centers for complex, multi-axis components  Agie Charmilles wire EDM systems for intricate features and fine surface finishes

Agie Charmilles wire EDM systems for intricate features and fine surface finishes  Zeiss inspection equipment for advanced quality control and dimensional verification

Zeiss inspection equipment for advanced quality control and dimensional verification  DMG MORI CNC milling and turning machines for precision production and complex geometries

DMG MORI CNC milling and turning machines for precision production and complex geometries Get high-quality manufactured CNC components made with the best materials from Owens Industries.