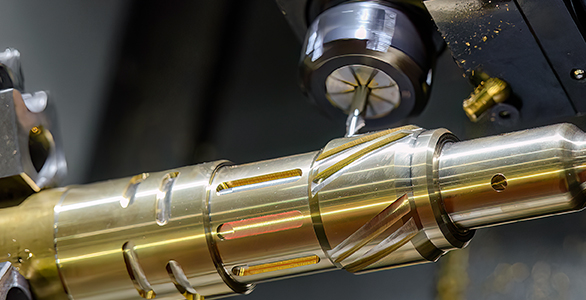

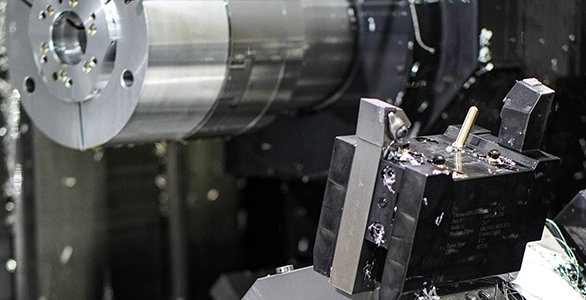

5-Axis Machining and Wire EDM Services for the Most Precise Components

For years, the city of Berkeley, CA has been a thriving economy that works together with many business associations catering to established businesses in specific industry sectors including tourism, technology, biotechnology, life sciences, medical devices and manufacturing. With California being the largest state economy in the United States, the state has always attracted a wide variety of lucrative industries, and Owens Industries has always manufactured the necessary components to keep these industries in business.

Owens’ precision CNC machining services come backed by experience, reputation, and the knowledge of how to produce a variety of custom components for a wide range of industries, including aerospace, manufacturing, and medical. Contact us today to learn more about our component manufacturing services for Berkeley businesses.

| |

Precision Machining for the Medical Industry

When it comes to medical machining, Owens Industries is the answer. Excelling in the craft of 5-axis machining and EDM, our engineers are a favorite among manufacturers of cardiovascular and orthopedic devices, surgical instrumentation, and implants. Owens Industries is the right choice for CNC machining of medical parts including:

- Surgical scissors – an essential instrument in virtually every medical procedure, when they’re not used to get into skin they are used to cut sutures. Surgical scissors are available in a number of shapes and sizes to fit the need of a wide range of applications – they are particularly small when used in eye surgeries. If you’re a surgical instrument manufacturer looking for a reliable CNC machine shop that can achieve incredible results, Owens is the answer! Stainless steel, straight, curved, flat, blunt, sharp – whatever the specifications of your scissors, we can meet your exact demands.

- Cannulas – medical products like IV cannulas are in high demand because they’re used in virtually every medical center across the world. Like many surgical instruments, they are available in multiple sizes, similar to needle gauges. We use state-of-the-art equipment like multi-axis milling and wire EDM to produce high precision cannulas that are safe and effective. The hollow metal tube and sharp, angled point of an IV cannula can be produced with exacting accuracies in our Wisconsin Machine Shop.

- Biopsy tubes – what is being biopsied determines the type of biopsy needle used during the procedure. Since not all biopsies are the same, there is no one size fits all needle for the task. We understand that safety, accuracy, and cost are all important factors when manufacturing medical tools; we help you win on all fronts with high quality, ultra-precision CNC machining services.

- Saw guides for bone surgery – helps orthopedic surgeons make the cleanest cuts possible, and protects against cutting too far into bone while sawing. Orthopedic procedures require the highest precision machined tools to produce the highest precision results. Whether you’re looking to outsource your medical machining needs permanently or require a custom saw guide for a future surgery, give us a call for a quote!

Contact the precision component machinists Berkeley businesses trust today to learn more about our capabilities.

Have problem parts or impossible components? In a hurry? Call on the expertise of Owens. Complex parts with tight deadlines are our specialty.

Get high-quality manufactured CNC components made with the best materials from Owens Industries.