Tungsten

Precision CNC Tungsten Machining Services For Complex Components

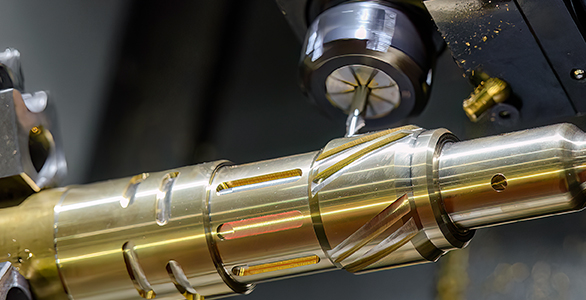

Owens Industries is a trusted name when it comes to providing advanced tungsten machining services. With CNC technology and state-of-the-art equipment, we can perform complex machining operations for many different CNC machining materials including tungsten. Our advanced machining capabilities include 4-axis and 5-axis milling, swiss machining, and even micromachining. This allows us to create the highest precision parts with the tightest tolerances. We can achieve tolerances as tight as 0.0005".

Owens Industries is a Wisconsin-based CNC machine shop, but we have been known nationally since 1944 for being on time, within budget, and within tolerance. We understand that each project is unique, which is why we offer custom tungsten machining services tailored to meet specific customer requirements. Our expertise in providing high-quality custom tungsten parts manufacturing and fabrication services is unmatched. Owens' commitment to quality assurance and inspection ensures that every precision tungsten CNC machining service we provide is of the highest standard.

Owens Industries

Tungsten Machining Services For Your Industry

Since 1944, designers and engineers have trusted Owens Industries to machine their components and parts from materials such as Tungsten. Owens Industries utilizes advanced CNC technology and machining equipment to offer ultra-precision Tungsten machining services. Our tungsten machining capabilities enable us to machine Tungsten parts with tight tolerances and complex geometries, making us the go-to partner for various industries.

Owens Industries Precision Machined Tungsten Components

Owens Industries has a long storied history of being able to deliver on time and within ultra-precision tolerances. Our precision Tungsten machining services include the machining of various components such as reactor vessels, emitters, blocks, panels, and other manufactured products. We use advanced machining techniques to achieve tight tolerance and precision in every part we machine. It doesn't matter if you are located near our Wisconsin-based CNC machining facility or not, we serve several different industries all across America in all 50 states.

To see more of our work, please visit our CNC product image gallery and our CNC product video gallery.

Here is an example list of Tungsten components that can be machined:

- Aerospace components, such as high-strength structural components and engine components

- Medical components, such as implantable devices and surgical instruments

- Marine components, such as ship fittings and underwater components

- Sports equipment, such as high-performance bicycle components and golf club heads

- Automotive components, such as engine components and suspension components

- Consumer goods, such as jewelry and high-end watches

- Chemical processing components, such as heat exchangers, piping components, and reactor vessels

Interested in utilizing Tungsten for your machined component? Contact Owens Industries today.

Tungsten Grades For CNC Machining

| Series | Main Alloying Element | Machinability | Properties | Typical Applications | Notes |

|---|---|---|---|---|---|

| AMS-T-21014 Class 1 | Tungsten | Very Difficult | Post Sinter Heat Treated, Brinell: 271, HRc: 28 | High-density applications, radiation shielding | Slow cutting speeds, brittle, prone to chipping |

| AMS-T-21014 Class 2 | Tungsten | Difficult | Sintered, Brinell: 286, HRc: 30 | Aerospace, defense, medical applications | Moderate cutting speeds, requires expertise |

| AMS-T-21014 Class 3 | Tungsten | Extremely Difficult | Sintered, Swaged after Sintering, Brinell: 442, HRc: 47 | Penetrators, kinetic energy projectiles | High tooling cost, requires specialized techniques |

| Pure Tungsten | Tungsten | Extremely Difficult | High melting point, high density, brittle, difficult to machine | Electrical applications, electronic components | Not recommended for general CNC machining |

| Alloyed Tungsten (e.g., copper alloys) | Copper, Iron, Nickel, etc. | Moderately Difficult | Non-magnetic, lower tensile strength, good heat resistance | Heating coils, electrical conductors | Careful selection based on alloy composition |

| Heavy Metal Tungsten Alloys | Thorium oxide | Very Difficult | Enhances thermionic electron transmission, high-density alloys | Radiation shielding, aerospace applications | Similar challenges to pure tungsten |

| Tungsten Carbide | Carbon | Difficult | Extremely hard, abrasive-resistant, good heat resistance | Cutting tools, mining drill bits, industrial machinery | Specialized CNC machines and toolpaths required |

| Cemented Carbide | Tungsten, Cobalt | Moderate | Strengthened with cobalt binder, less prone to vibrations | Metal cutting tools, boring equipment | Widely used for machining other materials, not recommended for direct tungsten machining |

The above information is a general overview, and specific grades within each series may have variations in alloying elements and characteristics. Please refer to the detailed specifications of individual Tungsten grades for more accurate information.

Tungsten CNC Services and Capabilities

Happy with our service? Leave us a 5-star review!