High-Complexity Manufacturing and Customized Parts Production

At Owens Industries, we proudly serve Wisconsin, offering top-tier CNC machine shop services with unparalleled precision and craftsmanship. Our expertise shines in intricate manufacturing and crafting customized parts, whether they're straightforward or advanced in design.

Based in Oak Creek, WI since our founding in 1944, Owens Industries has built a solid reputation across the nation, consistently delivering ultra-precision machining solutions, such as simultaneous 5-axis services, with an unwavering commitment to quality.

Have problem parts or impossible components? In a hurry? Call on the expertise of Owens. Complex parts with tight deadlines are our specialty.

Wisconsin's Trusted Source for Comprehensive CNC Machining

Owens Industries' extensive capabilities in CNC machining make us the preferred choice for diverse client needs in Wisconsin. We harness the power of the latest CNC machines, precision-calibrated to an accuracy within ±0.0001 inches. Our facility was specially designed and constructed for these ultra-high-end machining processes, utilizing temperature and dust control systems to ensure a meticulous finish and unmatched precision in every part crafted. We also hold all major certificates, guaranteeing our services meet exact specifications.

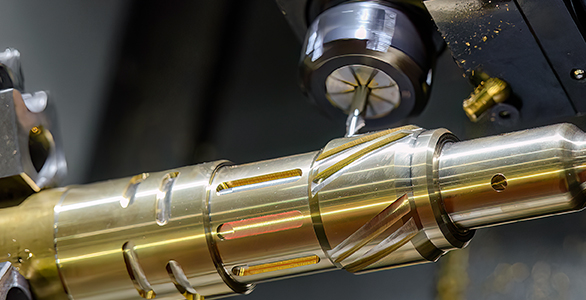

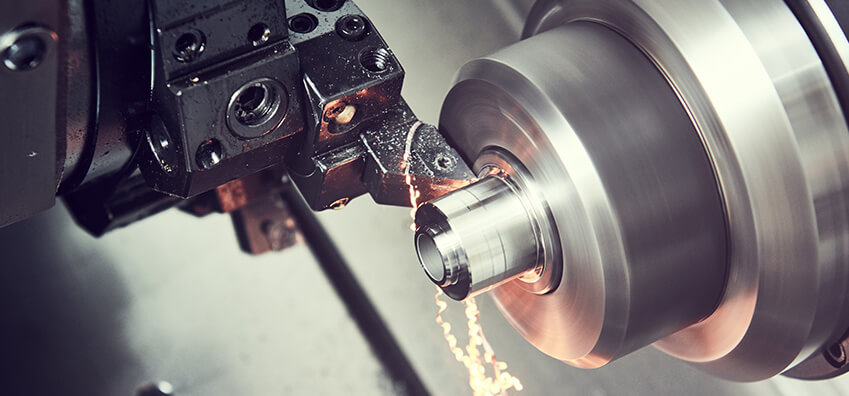

CNC Milling and Turning with Precision Craftsmanship

Our expertise in CNC milling and turning is well-recognized across Wisconsin. Utilizing state-of-the-art 5-axis machines, we handle a wide range of materials, including exotic metals such as Waspaloy and Hastelloy. Our machine capacity encompasses a broad spectrum of sizes up to 20” x 20” x 20”.

Custom CNC Parts: Ultra-Precision Engineering for Complex Needs

Owens's adaptability of CNC machining for Wisconsin businesses makes it possible to create even the most intricate designs. Our machines, operated by skilled personnel with 20 to 40 years of CNC experience, transform complex geometries into tangible parts, utilizing up to 5 axes of motion. Owens specializes in only the most complex and problem parts that other machining companies simply cannot produce.

Providing CNC Machining Services Across Wisconsin

At Owens Industries, we proudly serve the Wisconsin market with unmatched expert CNC services. Our advanced CNC services encompass simultaneous 5-axis CNC machining, wire EDM, lathe turning, milling, and precise deburring. Explore further to see how we customize each of these offerings to cater to the unique requirements of our Wisconsin clients.

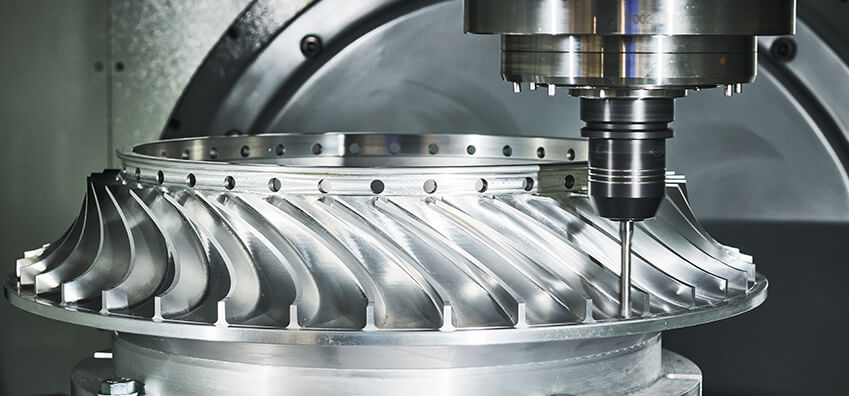

5-Axis CNC Machining Services

Our 5-Axis CNC machining services in Wisconsin enable complex part production with high precision. With multiple surface and angle machining capabilities in one operation, we ensure tight tolerances and quick turnarounds in Wisconsin.

Wire EDM Services

Our Wire EDM services in Wisconsin enable the creation of elaborate parts with remarkable tolerances down to 0.00004", ideal for complex designs that traditional CNC machining can't achieve.

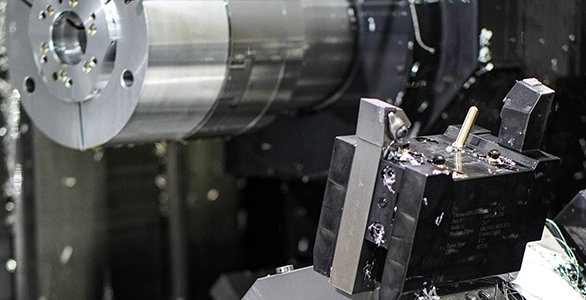

CNC Lathe Turning and Milling Services

Our CNC lathe turning and milling services in Alaska utilize state-of-the-art lathes and mills that allow us to create a wide range of parts with intricate geometries, maintaining exceptional precision and consistency.

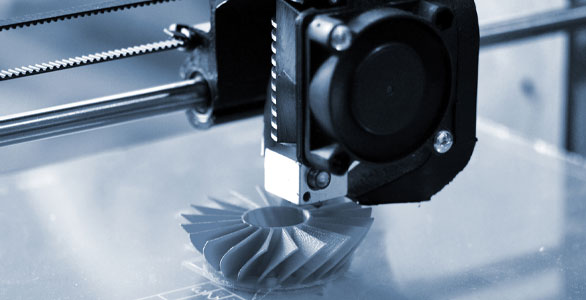

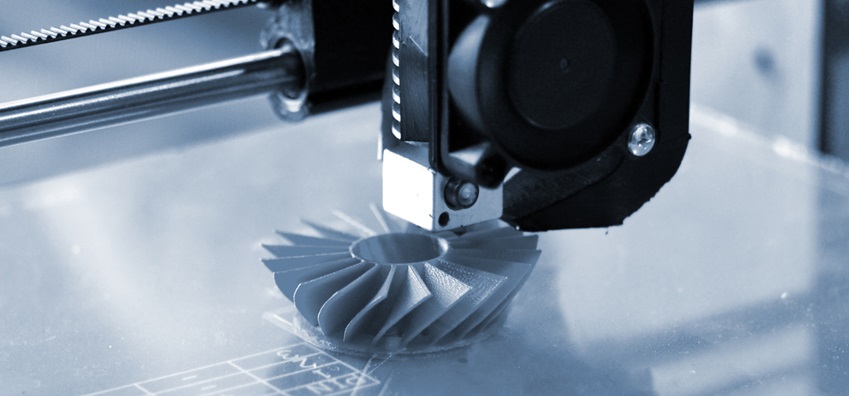

Precision 3D-Printed Parts

Our precision metal 3D printing services in Wisconsin produce complex components with ultra-tight tolerances. From high-performance alloys like Inconel and rhenium, we manufacture mission-critical parts for the aerospace and defense industries in Wisconsin.

CNC Services

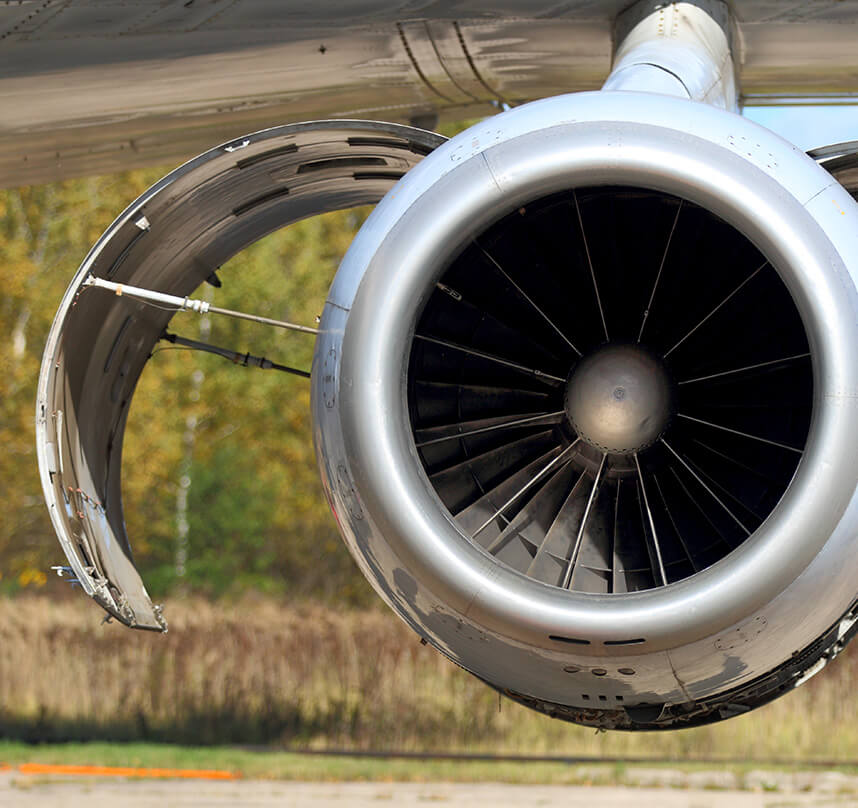

Crafting Complex Components for Major Industries

Our expertise isn't limited to crafting intricate parts; we're distinguished for creating components integral to critical applications. Whether it's a component for a cutting-edge NASA telescope, life-saving medical devices, or advanced military equipment, we understand the profound importance of every piece we mold.

Alaskan clients from sectors such as aerospace, medical, military & defense, and beyond entrust us with projects that require unparalleled precision and unwavering reliability. They depend on our components not only for their precision but also for their consistent performance in crucial situations.

Cutting Edge CNC Machines for Ultra-Precision Components

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

HERMLE 5-axis CNC machining centers for complex, multi-axis components

HERMLE 5-axis CNC machining centers for complex, multi-axis components  Agie Charmilles wire EDM systems for intricate features and fine surface finishes

Agie Charmilles wire EDM systems for intricate features and fine surface finishes  Zeiss inspection equipment for advanced quality control and dimensional verification

Zeiss inspection equipment for advanced quality control and dimensional verification  DMG MORI CNC milling and turning machines for precision production and complex geometries

DMG MORI CNC milling and turning machines for precision production and complex geometries Owens Industries: Leading CNC Machine Shop Serving Wisconsin

Owens Industries' influence resonates across the United States, and our Oak Creek, Wisconsin CNC machine shop has deeply impacted industries coast to coast, including Wisconsin. With unwavering precision and a dedication to customer satisfaction, we stand firm in our commitment to quality nationwide, including in Wisconsin.

When you opt for Owens Industries in Wisconsin, you choose a nationwide legacy of quality and excellence that fuels your projects, regardless of location. Forward your project details, and our Wisconsin representative will provide your personalized quote.

Explore Our CNC Career Opportunities

Fuel your CNC career with Owens Industries, LLC. We offer competitive pay, comprehensive benefits, and bonus-earning opportunities. Work in a world-class, climate-controlled facility in Oak Creek, WI. We are looking for talented individuals to join our expert family and grow with a company that values loyalty and precision.

Machined Components for local Wisconsin Industries

Based in Oak Creek, Owens is prepared to assist local Wisconsin businesses with their CNC machining needs. Businesses across the country and around the globe have been relying on Owens’ machinists for quality CNC services. We do not offer design services, but frequently help our clients with capabilities studies to determine the manufacturability of their components – resulting in improved designs and perfected applications.

Example CNC Machining Capabilities

- Aerospace electronics and instrumentation

- Optical measurement components

- Medical and surgical tools

- Guidance systems

- Watch industry components

- Microcomputer fittings and connectors

- Robotic mechanisms

- Fuel systems

- Defense systems

Serving All Major Wisconsin Cities

Owens Industries' commitment to quality and excellence extends across major cities in Wisconsin. We serve the CNC precision needs of Wisconsin, including but not limited to the following cities:

Get high-quality manufactured CNC components made with the best materials from Owens Industries.