Benefits of Owens Industries 5-Axis Machining Services

5-axis CNC machining is a cutting-edge manufacturing process that offers a wide range of benefits for manufacturers and engineers. With the ability to move a part or tool on five different axes simultaneously, 5-axis CNC machining allows for greater precision and accuracy in the production of complex parts and shapes. In this article, we will explore the top seven benefits of 5-axis CNC machining, including faster production times, improved surface finishes, and the ability to create complex shapes and contours. Keep reading to learn more about the many advantages of using 5-axis CNC machining in your manufacturing processes.

7 Benefits of 5-Axis CNC Machining

-

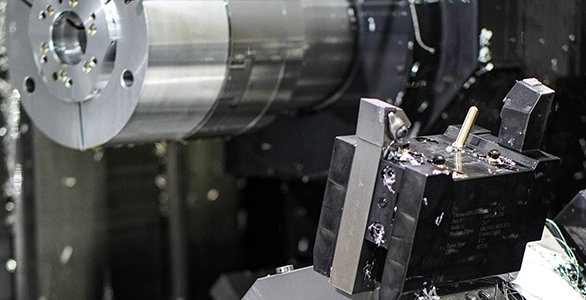

Increased efficiency: One of the major benefits of 5-axis CNC machining is its ability to increase the efficiency of the manufacturing process. With multiple axes of motion, 5-axis CNC machines are able to produce parts and components with a high level of accuracy and precision in a single setup. This eliminates the need for multiple setups, which can be time-consuming and prone to errors. In addition, 5-axis CNC machines are able to produce parts and components at a faster rate, which can help to reduce lead times and increase overall production efficiency.

-

Enhanced accuracy: Another benefit of 5-axis CNC machining is its ability to produce parts and components with a high degree of accuracy and precision. With the use of advanced computer numerical control technology, 5-axis CNC machines are able to maintain a high level of accuracy and precision throughout the machining process. This is especially important for industries that require precise parts and components, such as the aerospace and medical device industries.

-

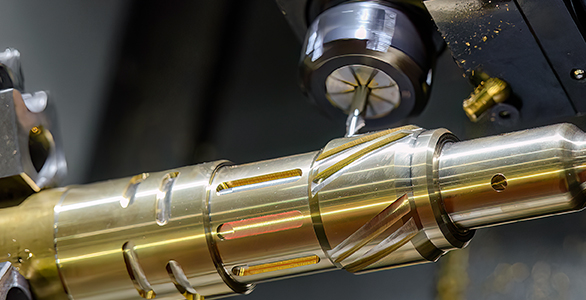

Increased complexity: 5-axis CNC machining is also able to produce parts and components with a high level of complexity. With multiple axes of motion, 5-axis CNC machines are able to produce parts and components with intricate shapes and features that would be difficult to produce using traditional machining methods. This increased complexity allows manufacturers to produce parts and components with a high degree of customization, which can be beneficial for industries that require unique or specialized components.

-

Better surface finish: 5-axis CNC machining is also able to produce parts and components with a better surface finish. With the use of advanced cutting tools and techniques, 5-axis CNC machines are able to produce parts and components with a smooth, polished finish. This is important for industries that require high-quality finishes, such as the automotive and aerospace industries.

-

Reduced need for secondary operations: Another benefit of 5-axis CNC machining is its ability to reduce the need for secondary operations. With multiple axes of motion, 5-axis CNC machines are able to produce parts and components with a high level of accuracy and precision in a single setup. This eliminates the need for additional machining or finishing operations, which can save time and reduce the overall cost of the manufacturing process.

-

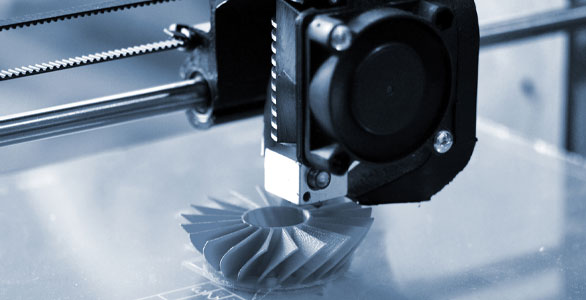

Greater design flexibility: 5-axis CNC machining also offers greater design flexibility. With the ability to produce parts and components with a high level of complexity, manufacturers are able to design and produce parts and components with a wide range of shapes and features. This flexibility allows manufacturers to meet the unique needs and requirements of their customers and produce parts and components that are tailored to specific applications.

-

Improved cost-effectiveness: Finally, 5-axis CNC machining is also able to improve the cost-effectiveness of the manufacturing process. By reducing the need for multiple setups and secondary operations, 5-axis CNC machining is able to reduce the overall cost of production. In addition, 5-axis CNC machining is able to produce parts and components with a high level of accuracy and precision, which can reduce the need for costly rework and improve the overall quality of the finished product.

Contact us today and speak with our 5-axis machinists to discuss your projects needs.

Happy with our service? Leave us a 5-star review!