Optics

Machine Shop for Microscope, Laser, and Telescope Components

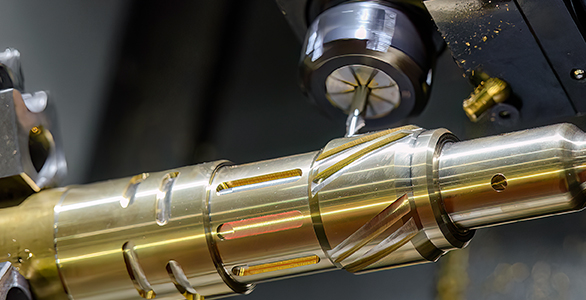

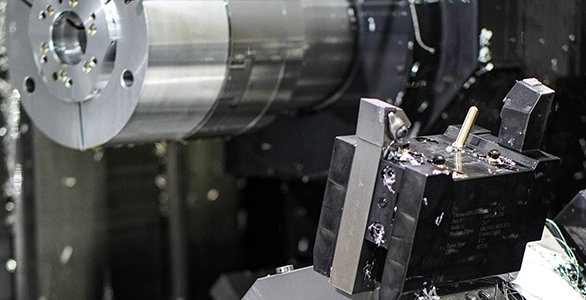

Optical industry components demand extreme precision for easy placement in complex equipment like microscopes, lasers, and telescopes for respected names in the industry like Zeiss. Owens Industry's advanced, German-made 5-axis CNC machines achieve tolerances of less than .0001, meeting the industry's rigorous demands. Owens understands each component's role, ensuring the parts fit perfectly into their assemblies.

We embrace challenges and never accept defeat. When tasked with creating an optical switch with 1,000 precisely angled holes meeting at a focal point four feet away, our team achieved what machine shops in the US, Germany, and Japan could not. For problem or impossible optical components, call upon the expertise of Owens.

CNC Machined Parts Meets the Demands of the Optical Industry

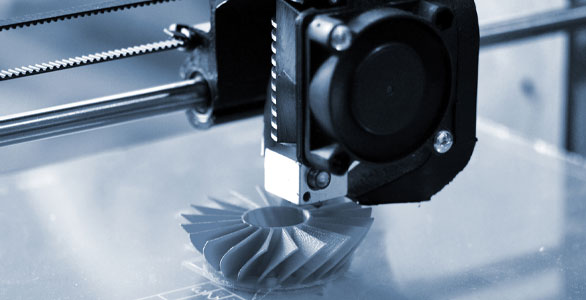

The smallest parts manufactured with the tightest tolerances are essential when working in the optical industry. Our CNC lathes offer the highest quality machined parts for businesses working with optical applications. From 5-axis machining to wire EDM, our CNC services will give your business the best precision manufactured parts at the most affordable cost.

Some of the CNC machined products manufactured by the optical industry include:

- Microscopes

- Telescopes

- Cameras

- Glasses

- And much more

Owens Industries continues to exceed quality standards in machining – from precision micromachining to wire EDM, our expert CNC services provide ultra-precision results made with the highest quality materials with the tightest tolerances. Contact us today to learn how you can take advantage of our CNC machining lathe.

Precision Machining for the Optical Industry

Electron microscopes require a lens holder – detailed enough to handle something as delicate as a lens but durable enough to protect it. Our expert machinists understood the highest tolerances are essential when dealing with something as minute as electrons, where the slightest error could be disastrous. We frequently design custom components that consistently meet these strict requirements and regulations. Our precision machining services for optical components are in high demand across the entire industry.

We can machine more than lens holders and assemblies. A recent project of ours was an optics assembly housing for a borescope. When engineering this particular component, we needed to ensure the lens assembly could accurately function while still being properly secured. We created a custom component that perfectly met the optical needs of our client.

Components We Build for the Optics Industry

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Blade Holder | Laser Eye Keratome | 4th-Axis Milling Center | Peek | Precision Miniature Plastic Machining |

| Barbed Tube Adapter | Fiber Optics Alignment | Mill/Turn | 17-4 ph Cond H900 | Drilling 0.025" Holes |

Cutting-Edge CNC Machines for Ultra-Precision Components

Owens Industries machines complex, tight-tolerance components using advanced German and Swiss CNC equipment built for ultra-precise manufacturing. Our CNC machines support high-spec industries where accuracy, repeatability and consistency directly impact performance, compliance and long-term reliability.

Our core equipment includes:

View our Success Gallery to see our work!