CNC Machining Capabilities

Tight Tolerance Machining

For Ultra-Precise Custom Parts

Owens Industries is proud to provide tight tolerance CNC machining services, combining ultra-precision with the ability to produce complex parts that meet client needs. Since 1944, we've mastered the ability to produce trouble parts of hard-to-machine materials that other manufacturers simply cannot handle. Our shop features the latest CNC machines, each calibrated to ensure accuracy within ±0.0001 inches.

Have problem parts or impossible components? In a hurry? Call on the expertise of Owens.

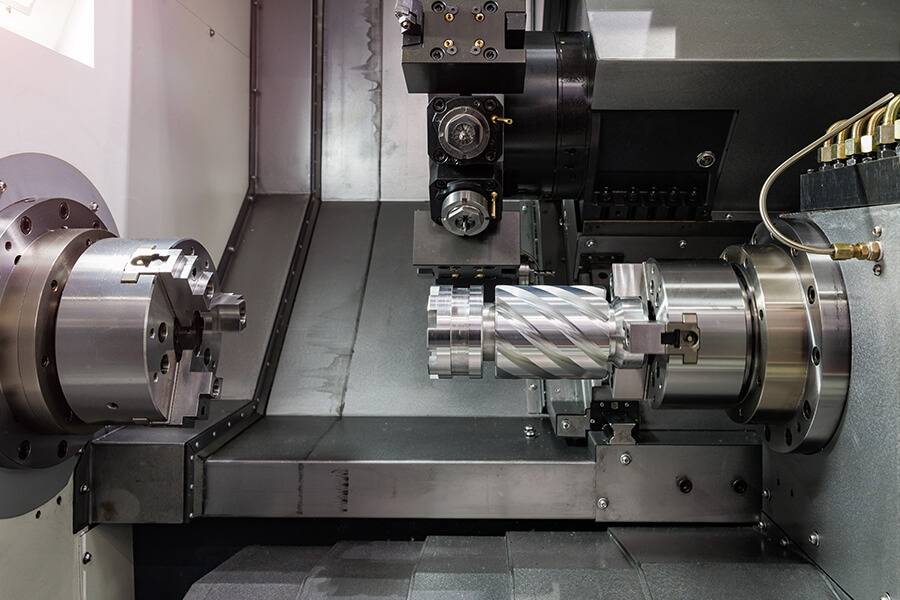

CNC Milling & Turning:

Superior Precision and Finish

At the heart of our services are CNC milling and turning. Using advanced 5-axis machines, we can work with various materials, including steel, aluminum, and exotic metal like Waspaloy and Hastelloy. Our machines can handle a range of part sizes, from small intricate components to large-scale parts up to 20” x 20” x 20”, 16” length x 12” diameter and down to .250”x.250”.250”, 250 diameter .5” length.

Our skilled machinists pay close attention to detail, ensuring that the finished parts meet the design specifications with accuracy down to micrometers. From tight tolerance features to the smooth surface finish, our team is committed to delivering a product that not only fits perfectly into your assembly but also looks and feels high-quality.

Custom CNC Parts:

Ultra-Precision Machining for Complex Designs

The beauty of CNC machining lies in its adaptability. No matter how complex your designs are, our machines and expert team can bring them to life. Utilizing up to 5 axes of motion, we can produce parts with intricate geometries that would be impossible with conventional machining techniques.

Whether it's a one-off custom part for a special project or a complex machined part for mass production, our team is up for the challenge. We bring a wealth of experience and problem-solving skills to every project, ensuring we can produce your custom parts to the exact specifications, meeting even the most stringent tolerances.

Additional CNC & Manufacturing

Services

At Owens Industries, we pride ourselves on being a comprehensive solution provider, and we offer an array of additional manufacturing services alongside our premier tight tolerance CNC machining capabilities. Our range of services enables us to deliver fully finished, high-precision components that meet your exact specifications.

5-Axis CNC Machining Services

Our 5-axis CNC machining services allow us to produce complex machined components with high precision. This technology enables machining from multiple surfaces and angles in one operation, reducing the need for tool changes and set-up times. As a result, we can achieve tighter tolerances and faster turnarounds.

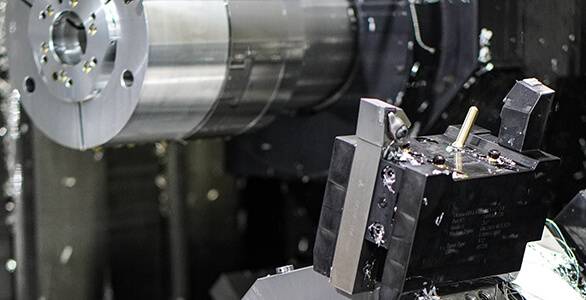

EDM Machining Services

Electrical Discharge Machining services at Owens Industries offer precision manufacturing of intricate parts. With EDM, including wire EDM and ram/sink/plunge EDM, we can achieve general tolerances down to .0005" (0.0127 mm), making it an ideal choice for complex geometries that are not feasible with conventional CNC machining.

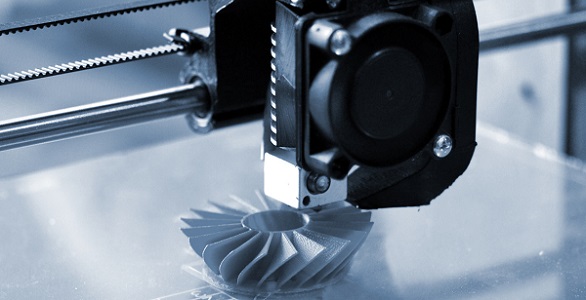

Metal 3D Printed Parts Services

Owens Industries offers cutting-edge additive manufacturing to produce complex metal 3D printed parts in the aerospace and defense sectors. Our specialized capabilities, combined with traditional machining techniques, allow us to create complex geometries, lightweight components and custom parts with unmatched precision.

Mill Turn Machining Services

As a leader in precision mill turn machining, Owens leverages advanced techniques to seamlessly integrate milling and turning operations with unparalleled efficiency. With Owens, you gain access to cutting-edge mill turn manufacturing capabilities that deliver reliable components of intricate geometries and diverse materials.

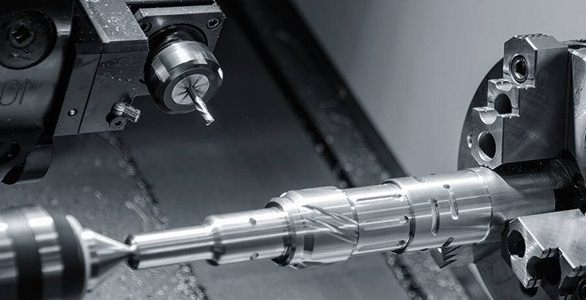

CNC Lathe Turning & Milling Services

Owens offers comprehensive turning and milling services using advanced CNC lathes and mills. These machines enable us to produce many complex geometry parts with precision and consistency. We can hold general tolerances down to .0025" (.0635 millimeters), ensuring your parts meet exact specifications.

Additional CNC Machining Services

Owens Industries offers additional precision CNC services, including secondary processes such as heat treatments and surface finishing.

Materials

CNC Machining Materials Trusted by Owens Industries

Owens Industries understands that different applications require different materials, each with its unique properties. That's why we offer a wide array of CNC machining materials to meet various project requirements, whether it's lightness and durability or strength and resistance.

- Brass

- Copper

- Stainless Steel

- Tool Steel

- Alloy Steel

- Aluminum

- Hastelloy

- Inconel

- Invar

- Maraging Steel

- Titanium

Brass

Brass is a metal known for its easy machinability and good electrical conductivity. It is ideal for applications requiring low friction, such as gears, locks, and musical instruments.

| Brass | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C36000 | UNS C36000 | CUZN39PB3 | CuZn39Pb3 |

| C46400 | UNS C46400 | CuZn38Al | Naval Brass |

| C93200 | UNS C93200 | Saems 660 | Bearing Bronze |

| C48500 | UNS C48500 | CuZn39Sn1 | Leaded Muntz Metal |

| C26000 | UNS C26000 | CUZN30 | Cartridge Brass |

| C37700 | UNS C37700 | CUZN40PB2 | Forging Brass |

Copper

Copper is excellent at conducting heat and electricity, making it perfect for electrical uses like busbars and wire connectors. It is easily recognized by its shiny reddish-orange color and is also used in plumbing and roofing.

| Copper | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C11000 | UNS C11000 | Cu-ETP | Electrolytic Tough Pitch (ETP) Copper |

| C10100 | UNS C10100 | OF-OK | Oxygen-Free Electronic (OFE) Copper |

| C10200 | UNS C10200 | OF-Cu | Oxygen-Free (OF) Copper |

| C28000 | UNS C28000 | CuZn40 | Muntz Metal |

| C14500 | UNS C14500 | TeCu | Tellurium Copper |

Stainless Steel

Stainless steel is known for its strength, heat, and corrosion resistance, along with its durability and attractive appearance. These qualities make it suitable for a wide range of uses, including kitchenware, medical instruments, and construction.

| Stainless Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 316L | UNS S31603 | X2CrNiMo17-12-2 | Stainless Steel 316L |

| 304 | UNS S30400 | X5CrNi18-10 | Stainless Steel 304 |

| 17-4 PH | UNS S17400 | X5CrNiCuNb16-4 | Stainless Steel 17-4 PH |

| 303 | UNS S30300 | X8CrNiS18-9 | Stainless Steel 303 |

| 420 | UNS S42000 | X20Cr13 | Stainless Steel 420 |

| 440C | UNS S44004 | X105CrMo17 | Stainless Steel 440C |

Tool Steel

Tool steels are hard, stiff, and resistant to abrasion, making them perfect for manufacturing industrial tools. Their robustness is essential for cutting, drilling, and molding applications in various industries.

| Tool Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| D2 | UNS T30402 | 1.2379 | X155CrVMo12-1 |

| M2 | UNS T11302 | 1.3343 | HS6-5-2C |

| A2 | UNS T30102 | 1.2363 | X100CrMoV5-1 |

| S7 | UNS T41907 | 1.2355 | 50CrMoV13-15 |

| O1 | UNS T31501 | 1.2510 | 100MnCrW4 |

| H13 | UNS T20813 | 1.2344 | X40Cr |

Alloy Steel

Alloy steels include additional elements beyond carbon, which improve their hardness, toughness, and resistance to fatigue and wear. These steels are widely used in construction, automotive, and machinery due to their enhanced properties.

| Alloy Steel | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 4140 | 1.7225 | 708M40 | 42CrMo4 |

| 4340 | 1.6565 | 817M40 | 40NiCrMo6 |

| 8620 | 1.6523 | 805M20 | 20NiCrMo2 |

| 52100 | 1.3505 | 100Cr6 | SUJ2 |

| 4142 | 1.7227 | 708M40T | 41CrMoS4 |

| 6150 | 1.8159 | 735A51 | 50CrV4 |

Aluminum

Aluminum alloys are lightweight and strong, with excellent thermal and electrical conductivity. They are also resistant to corrosion and can be anodized for added protection, making them ideal for aerospace and packaging industries.

| Aluminum Alloy | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu |

| 6082-T651 | 3.2315 | 64430 | AlSi1MgMn |

| 6060 | 3.3206 | EN AW-6060 | AlMgSi |

| 5052 | EN AW-5052 | 3.3523 | AlMg2,5 |

| 2017A | 3.1325 | 24530 | AlCu4MgSi |

Hastelloy

Hastelloy is a group of nickel alloys known for their high resistance to corrosion, pitting, and stress-corrosion cracking. They are often used in harsh environments like chemical processing and aerospace, where durability is crucial.

| Hastelloy | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C276 | UNS N10276 | 2.4819 | NiMo16Cr15W |

| C22 | UNS N06022 | 2.4602 | NiCr21Mo14W |

| B-2 | UNS N10665 | 2.4617 | NiMo28 |

| X | UNS N06002 | 2.4665 | NiCr22Fe18Mo |

| C2000 | UNS N06200 | 2.4675 | NiCr23Mo16Cu |

| G-30 | UNS N06030 | 2.4603 | NiCr29Mo9Fe |

Inconel

Inconel is a strong, corrosion-resistant nickel alloy, ideal for challenging aerospace applications. It can withstand extreme temperatures and pressures, making it suitable for jet engines and gas turbines.

| Inconel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 718 | UNS N07718 | 2.4668 | NiCr19Fe19Nb5Mo3 |

| 625 | UNS N06625 | 2.4856 | NiCr22Mo9Nb |

| 600 | UNS N06600 | 2.4816 | NiCr15Fe |

| X-750 | UNS N07750 | 2.4669 | NiCr15Fe7TiAl |

| 601 | UNS N06601 | 2.4851 | NiCr23Fe |

| 725 | UNS N07725 | 2.4668 | NiCr19Fe19Nb5Mo3 |

Invar

Invar is a nickel alloy with very low thermal expansion, making it highly stable and perfect for precision applications such as instrumentation and aerostructure molds. It is also used in scientific instruments where dimensional stability is critical.

| Invar | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 36 | UNS K93600 | 1.3912 | FeNi36 |

| 42 | UNS K94200 | 1.3917 | FeNi42 |

| 48 | UNS K94800 | 1.3922 | FeNi48 |

| 32-5 | UNS K94610 | 1.3911 | FeNi32-5 |

| 42-6 | UNS K94620 | 1.3913 | FeNi42-6 |

| 46 | UNS K94630 | 1.3914 | FeNi46 |

Maraging Steel

Maraging steels are ultra-high-strength steels that are easy to machine and weld without causing distortion. They gain their exceptional hardness and toughness from a special heat-treating process, making them suitable for aerospace and tooling applications.

| Maraging Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 200 | UNS K93120 | 1.6359 | 20Ni Maraging Steel C200 |

| 250 | UNS K92890 | 1.6358 | 18Ni Maraging Steel C250 |

| 300 | UNS K93120 | 1.6354 | 18Ni Maraging Steel C300 |

| 350 | UNS K93160 | 1.6356 | 18Ni Maraging Steel C350 |

| 400 | UNS K91460 | 1.6352 | Custom 465 Stainless |

| 500 | UNS K92810 | 1.6354 | Custom Age 625 Plus |

Titanium

Titanium is a lightweight metal with excellent strength, low thermal expansion, and high corrosion resistance. Its ability to be sterilized and its biocompatibility make it unique, especially in medical implants and aerospace components.

| Titanium Grade | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 5 (Ti-6Al-4V) | UNS R56400 | 3.7165 | Ti-6Al-4V |

| 2 | UNS R50400 | 3.7035 | CP Titanium |

| 23 (Ti-6Al-4V ELI) | UNS R56401 | 3.7165 | Ti-6Al-4V ELI |

| 9 (Ti-3Al-2.5V) | UNS R56320 | 3.7195 | Ti-3Al-2.5V |

| 7 (Ti-0.2Pd) | UNS R52400 | 3.7235 | Ti-0.2Pd |

| 12 (Ti-0.3Mo-0.8Ni) | UNS R53400 | 3.7105 | Ti-0.3Mo-0.8Ni |

Tolerances

Achievable Tolerances in Owens Industries' Machining Services

At Owens Industries, precision is paramount. For industries requiring complex and ultra-precise components, tolerances are critical to ensure each part functions exactly as designed. Owens Industries applies advanced tolerances to deliver unmatched quality across our key CNC services: 5-axis machining, EDM machining, mill-turn machining, and CNC lathes/turning.

| Machining Service | 5-Axis Machining | EDM Machining | Mill-Turn Machining | CNC Lathes/Turning | Metal 3D Printed Parts |

|---|---|---|---|---|---|

| Maximum Part size | 28" x 24" x 15" | 13.5" x 21.5" | 14" dia x 16" oal | 10" dia x 10" oal | 28" x 24" x 15" |

| Standard Lead Time | 12 weeks | 12 weeks | 12 weeks | 10 weeks | 12 weeks |

| General Tolerances | .001" | .0005" | .0025" | .0025" | .001" |

| Precision Tolerances | .0001" | .00005" | .0005" | .00025" | .0001" |

| Minimum Feature Size | 250 x .250 x .250 | .01 x .01 x .01 | .060" dia x .050" oal | .060" dia x .050" oal | .250 x .250 x .250 |

| Minimum Surface Finish | 8 | 8 | 8 | 8 | 8 |

| Standard Surface Finish | 64 | 32 | 32 | 32 | 32 |

*Standard delivery dependent on workloads. Call Owens for current lead times.

As machined (Ra 3.2μm / Ra 126μin)

The surface is left with visible tool marks from the machining process, suitable for functional parts where cosmetic appearance is not a priority but surface roughness meets the required specifications.

Smooth machining (Ra 1.6μm / Ra 63μin)

The surface is refined to a smoother finish, reducing visible tool marks and ideal for parts where a smoother finish is desired, offering improved aesthetics and potential reduction in friction.

Fine machining (Ra 0.8μm / Ra 32μin)

The surface is further refined to a finer finish, minimizing visible tool marks and excellent for applications requiring a high level of surface refinement, such as precision components or parts with strict cosmetic requirements.

Polishing (Ra 0.8μm / Ra 32μin)

The surface is buffed to a high shine, resulting in a smooth and reflective appearance, making it ideal for achieving a mirror-like finish on decorative components or parts where low friction and easy cleaning are desired.

Brushed (Ra 1.2μm / Ra 47μin)

The surface is textured with fine parallel lines, providing a distinctive appearance, and is well-suited for applications that call for a unique textured appearance, such as architectural accents or consumer products.

Electroless Nickel Plating

A nickel coating is deposited onto the surface using an autocatalytic process, offering corrosion resistance and uniform coating thickness, ideal for wear, abrasion, and corrosion resistance in industrial machinery components or parts subjected to harsh environments.

Bead Blasted + Anodized type II

The surface is first bead blasted for a textured look and then anodized, providing a combination of texture and aesthetic appeal, commonly used in architectural elements, consumer electronics, or decorative pieces.

As machined + Anodized type II

The surface is machined and then anodized with a standard, protective finish, suitable for providing a protective and decorative finish for machined parts, often used in aerospace, automotive, or electronics industries.

Brushed + Anodized type II (Glossy)

The surface is brushed to create fine parallel lines and then anodized with a glossy finish, ideal for achieving a textured and visually appealing finish on components requiring both aesthetics and corrosion resistance, such as architectural hardware or consumer products.

Bead blasted + Anodized type II (Matte)

The surface is bead blasted for a matte texture and then anodized with a standard finish, well-suited for applications that require a matte texture along with enhanced corrosion protection, commonly used in outdoor equipment, automotive trim, or signage.

As machined + Anodized type III (Hardcoat)

The surface is machined and then anodized with a thicker, hard coat finish for enhanced durability, providing an exceptionally durable and wear-resistant finish for parts subjected to high wear or extreme conditions, often used in aerospace, military, or industrial applications.

Brushed + Electropolished (Ra 0.8μm / Ra 32μin)

The surface is brushed to create parallel lines and then treated with an electropolishing process to achieve a smooth and polished appearance, ideal for achieving a smooth, polished, and aesthetically pleasing finish on stainless steel components, commonly used in medical devices, food processing equipment, or architectural applications.

Chromate Conversion Coating

The surface is treated with a chemical conversion process to create a protective and corrosion-resistant coating, often resulting in a yellowish or iridescent appearance, suitable for improving corrosion resistance and providing a protective layer on aluminum surfaces, commonly used in aerospace, automotive, or electrical applications.

Exceptional CNC Machining Services with Nationwide Reach

At Owens Industries, we are proof that you don't have to be everywhere to make a national impact. Through our advanced CNC machining capabilities and steadfast commitment to quality, we've become a trusted partner to clients across the length and breadth of the United States.

Our CNC machine shop in Oak Creek, Wisconsin, our influence is deeply felt from coast to coast, thanks to our industry-leading precision and dedication to customer satisfaction. Regardless of your location, we're steadfast in providing high-standard services that are just a call away, reinforcing our national reputation as a reliable precision machining partner.

Whether you're in the aerospace industry on the West Coast or an automotive manufacturer on the East Coast, our promise remains the same: to deliver superior precision machining services that surpass your expectations and contribute to your success in your respective market.

When you choose Owens Industries, you're choosing a nationwide commitment to quality and excellence that fuels your projects, no matter where you are. Send us the details of your project and one of our reps will reach out to you with your project quote.

CNC Machining Surface Treatments

Bead blasted

The surface is treated with abrasive particles to create a uniform matte texture, enhancing the grip or aesthetic appearance of surfaces, commonly used in handles, tools, or components requiring a matte texture.

Powder coated

A dry powder is applied to the surface and cured to form a durable, even, and decorative finish, making it ideal for providing durable and attractive finishes on various surfaces, including metal furniture, automotive parts, or outdoor equipment.

Black oxide

The surface is chemically treated to create a black-colored oxide layer, improving corrosion resistance and providing an aesthetic appearance, suitable for applications requiring corrosion resistance and a visually appealing black finish, often used in firearms, tools, or decorative hardware.

FAQ

CNC Machining Capabilities FAQs

What is the difference between CNC and machining?

CNC stands for Computer Numerical Control, which refers to the automation of machine tools using computer programming. On the other hand, machining is a broader term that encompasses various processes of shaping and removing material to create a desired part or product. CNC machining specifically refers to the use of computer-controlled machines to perform precise and automated machining operations.

What do CNC companies do?

CNC companies specialize in providing CNC machining services to industries and individuals. These companies utilize advanced CNC machines and technologies to manufacture custom parts and products according to specific designs and requirements. They work with a wide range of materials and provide services such as milling, turning, drilling, and more. CNC companies often collaborate with clients to optimize designs, ensure precision, and deliver high-quality finished products.

Who needs CNC services?

CNC services are valuable for a diverse range of industries and individuals. Manufacturers across sectors such as aerospace, automotive, electronics, and medical frequently require CNC machining services to create intricate and precise components. Additionally, engineers, designers, inventors, and hobbyists seeking custom parts can benefit from the capabilities offered by CNC companies. Essentially, anyone in need of accurate, complex, and consistent parts can benefit from CNC services.

What is CNC machining?

CNC machining is a manufacturing process that utilizes computer-controlled machines to shape and remove material from a workpiece. It involves precise movements of cutting tools to create intricate designs and dimensions as per the programmed instructions. CNC machining offers high accuracy, repeatability, and automation, enabling the production of complex parts with tight tolerances. This process is widely used in various industries to create parts, functional components, and finished products.

How does CNC machining work?

CNC machining works by translating computer-generated designs into precise instructions for a CNC machine. First, the design is created using Computer-Aided Design (CAD) software. The CAD file is then converted to a format readable by CNC machines. Next, the CNC machine operator sets up the workpiece, secures it, and loads the necessary tools. The CNC machine follows the programmed instructions, controlling the tool's movement and cutting parameters to shape the workpiece accurately. Throughout the process, sensors and feedback systems help maintain precision and quality.

What are the advantages of CNC machining over traditional machining methods?

CNC machining offers several advantages over traditional machining methods:

- Automation and precision: CNC machines operate with high precision and consistency, reducing human error and ensuring accurate results.

- Complex designs: CNC machines can execute intricate designs and produce complex shapes that are challenging or impossible with manual machining.

- Efficiency and speed: CNC machining allows for faster production rates, simultaneous operations, and reduced setup times, leading to increased productivity.

- Repetition and consistency: CNC machines can repeatedly produce identical parts, ensuring consistency and uniformity across large production runs.

- Versatility: CNC machines can work with a wide range of materials, including metals, plastics, wood, and composites, accommodating diverse manufacturing needs.

By harnessing these advantages, CNC machining optimizes manufacturing processes, enhances product quality, and streamlines production workflows.