Stainless Steel

Precision CNC Stainless Steel Machining Services for Complex Components

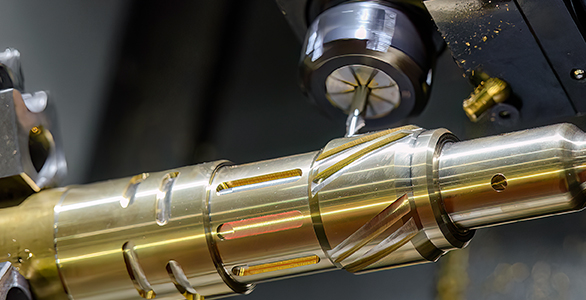

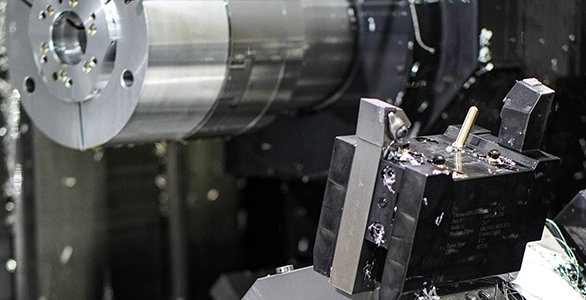

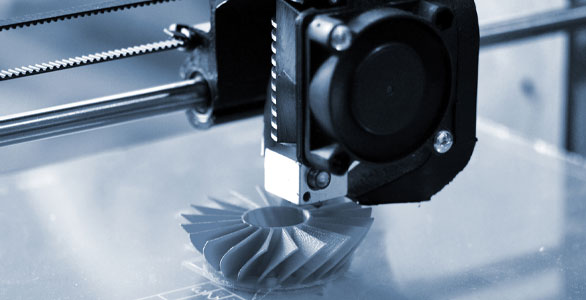

Owens Industries is a trusted name when it comes to providing advanced stainless steel machining services. With CNC technology and state-of-the-art equipment, we can perform complex machining operations for many different CNC machining materials including stainless steel. Our advanced machining capabilities include 4-axis and 5-axis milling, swiss machining, and even micromachining. This allows us to create the highest precision parts with the tightest tolerances. We can achieve tolerances as tight as 0.0005".

Owens Industries is a Wisconsin-based CNC machine shop, but we have been known nationally since 1944 for being on time, within budget, and within tolerance. We understand that each project is unique, which is why we offer custom stainless steel machining services tailored to meet specific customer requirements. Our expertise in providing high-quality custom stainless steel parts manufacturing and fabrication services is unmatched. Owens' commitment to quality assurance and inspection ensures that every precision stainless steel CNC machining service we provide is of the highest standard.

Owens Industries

Stainless Steel Machining Services For Your Industry

Since 1944, designers and engineers have trusted Owens Industries to machine their components and parts from materials such as Stainless Steel. Owens Industries utilizes advanced CNC technology and machining equipment to offer ultra-precision Stainless Steel machining services. Our Stainless Steel machining capabilities enable us to machine Stainless Steel parts with tight tolerances and complex geometries, making us the go-to partner for various industries.

Owens Industries Precision Machined Stainless Steel Components

Owens Industries has a long storied history of being able to deliver on time and within ultra-precision tolerances. Our precision Stainless Steel machining services include the machining of various components such as handles, medical devices, lab instruments, automotive parts, weld ferrules, and more. We use advanced machining techniques to achieve tight tolerance and precision in every part we machine. It doesn't matter if you are located near our Wisconsin-based CNC machining facility or not, we serve several different industries all across America in all 50 states.

To see more of our work, please visit our CNC product image gallery and our CNC product video gallery.

Here is an example list of Stainless Steel components that can be machined:

- Electronic components, such as resonators, oscillators, and frequency control components

- Mechanical components, such as gears, gauges, and measuring instruments

- Optical components, such as telescopes, spectrometers, and mirrors

- Aerospace components, such as high-precision spacecraft components and navigation systems

- Scientific instruments, such as cryogenics, spectroscopy, and metallurgy components

- Automotive components, such as fuel injectors and engine components

More CNC Components We Manufacture With Stainless Steel

| Part | Application | Industry | Machining Process Used | Specific Feature |

|---|---|---|---|---|

| Actuator, Arm | Night Vision Goggles | Military | EDM Wire | 20 Tooth Ratchet Profile |

| Check Valve | Brake Fluid Flow Control | Aerospace | Precision Turning | 32 Micro finish on all Surfaces |

| Pivot Ball | Military Aircraft | Defense | Turning and Spot Welding | Welding Carbide Ball to Stainless Steel Stem |

| Valve Seat | Air Flow Regulator | Aerospace | Mill/Turn | Diameters held within 0.0005" Concentricities |

| Read Head | Signal Encoder | Military | 5-Axis Milling and Grinding | Precision Grinding of Flat Surfaces |

| Armature Assembly | Pneumatic Valve | Commercial Airlines | Lathe, Mill w/ 4th axis Indexer | Welded/Polished Assembly |

| Solenoid Valve Seat | Hydraulic Piston Seat | Mining | Hard Turning | Ballize Seal Seat to 0.078" Profile |

| Flexure | Electronic Control | Research and Development | Fine Wire EDM | EDM Wire 0.015" Wide Slot |

| Grid Clamp | Satellite Component | Space Research | CNC Turn | Turn 0.044" Thick Ring |

| Body, Column, Housing | Optics | Research | Precision Turn and 5-Axis Milling | 2 Micron Tolerance Over 10.0" Length |

| Octopole Housing | Beam Orientation | Research and Development | Turning, Milling, and Welding | Assembly Alignment of 5 Microns or Less |

| Nozzle Adjustment Plate | Directional Adjustments | Industrial Printing | 3-Axis Machining | Machine Part Around .0787" Pivot Point |

| Outlet Adapter | Fluid Flow | Hydraulics | 3-Axis milling | Machining Varied SAE Ports |

| Gunbody | Ink Jet Printer Head | Industrial Printing | 4-Axis milling | Machining and Welding of A Sealed Manifold |

| Drilled Gutter Block | Ink Suction Block | Industrial Printing | 4-Axis milling | Drilling 8 Burr Free Connected Holes |

| Mixer Head Insert | Spray Nozzle | Automotive | 5-Axis milling | Required to mill axial slots at acute angles |

| Spray Nozzle | Urethane Application | Automotive | EDM Wire | Locating Spray Slot within 0.0005" |

| Micro Tip | Instrument Cap | Medical | Micro Turning | Micro Wire EDM |

| Hemisphere | Ink Jet Nozzle | Industrial Printing | Precision Fine Turn Work | Polished 8 Micro Finish on 0.120" Diameter |

| Drive Rod | Ink Jet Piston | Industrial Printing | Swiss Turning | Burr Free Rod with 0.0005" Straightness |

| Nozzle Housing | Circuit Board Manufacturing | Electronics | Turning and EDM | EDM Wire 3 Degree Taper Cone with 8 Micro Finish |

Stainless Steel Grades For CNC Machining

| Series | Main Alloying Element | Properties | Typical Applications | Machinability | Weldability |

|---|---|---|---|---|---|

| Austenitic (e.g., 304, 316) | Chromium, Nickel | Excellent formability, weldability, corrosion resistance | Food processing, chemical industry, architectural elements | Good | Excellent |

| Martensitic | Chromium | High toughness, requires aging and heat treatments | Cutlery, surgical instruments, aerospace components | Moderate | Good |

| Ferritic | Chromium | Good corrosion resistance, part of AISI 400 family | Automotive parts, kitchen appliances, architectural features | Good | Good |

| Duplex | Chromium, Nickel | Combines ferritic and austenitic structures, enhanced properties | Chemical processing, oil and gas, marine applications | Moderate to difficult | Good |

| Precipitation-Hardening | Various (e.g., Ti, Cu) | Age-hardening process, high strength | Aerospace components, high-stress applications | Difficult | Moderate |

The above information is a general overview, and specific grades within each series may have variations in alloying elements and characteristics. Please refer to the detailed specifications of individual Stainless Steel grades for more accurate information.

Interested in utilizing Stainless Steel for your machined component? Contact Owens Industries today.

Stainless Steel CNC Services and Capabilities

Happy with our service? Leave us a 5-star review!