Military & Defense

Precision Components Manufactured for Mission-Critical Systems

Owens Industries is a trusted partner to the military and defense industry, delivering ultra-precise components with complete confidentiality. Leading organizations rely on us as their go-to CNC machine shop for tight-tolerance parts, complex builds and fast turnaround times.

Our machinists manufacture mission-critical components directly from your models to deliver precise results without needing full design context. All parts are produced in-house at our AS9100 & ITAR-certified Milwaukee facility, with strict confidentiality agreements covering employees, vendors and visitors.

From early-stage development to emergency replacements, our team delivers dependable results when others can’t. Have problem parts or urgent builds? Trust Owens to get it done.

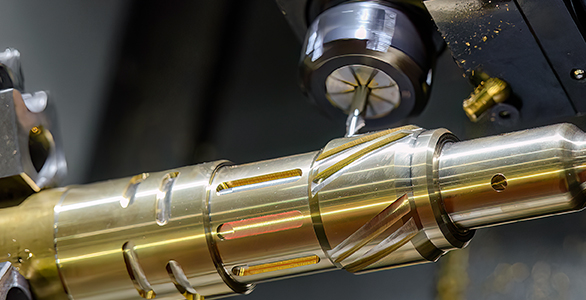

Precision Military Components Made with Our CNC Lathes

When you need precision parts for military applications, Owens Industries uses CNC machining lathes to produce components with the tightest tolerances. Our team builds military-grade parts using high-quality materials and advanced processes—from 5-axis milling to micromachining. Our CNC lathes deliver intricate parts with accuracy and efficiency, all at a competitive cost.

We work with lightweight and high-performance materials, fabricating complex components to exact specifications. CNC lathes are ideal for manufacturing small, detailed parts with repeatable precision for high-stakes military use.

Our CNC lathes manufacture various components, including:

- Screws

- Spacers

- Artillery Components

- Fighter Aircraft Components

- Missile Components

When military-grade parts demand tight tolerances and absolute reliability, Owens Industries delivers. Contact us today to learn more about our CNC machining services.

Finely Crafted Components Made for Military Aircraft

The CSTRS team hired Owens Industries to manufacture the guillotines for their naval helicopter. Our reliable CNC machine shop manufactured their parts with the highest level of quality, accuracy and precision, and their team was 100% satisfied with our work. Our professional CNC technicians met every one of their needs with our expert machining services, and we can help your company with whatever you need. No matter if you need 5-axis milling, 3D metal printing or CNC machining, Owens Industries is here to help you.

Materials

High-Quality Materials for Reliable Military Components

Owens Industries machines defense components from durable, high-performance materials proven to withstand extreme conditions. Whether you're working on flight hardware, weapon systems or rugged field equipment, we tailor each part to your exact requirements.

Our team works with a wide range of metals and alloys selected for strength, heat resistance, corrosion protection and mission-readiness. Every material is precision-machined and backed by decades of experience in military manufacturing. We routinely fabricate custom components from materials such as:

- Copper

- Stainless Steel

- Aluminum

- Inconel

- Invar

- Titanium

- Kovar

Copper

Copper is excellent at conducting heat and electricity, making it perfect for electrical uses like busbars and wire connectors. It is easily recognized by its shiny reddish-orange color and is also used in plumbing and roofing.

| Copper | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| C11000 | UNS C11000 | Cu-ETP | Electrolytic Tough Pitch (ETP) Copper |

| C10100 | UNS C10100 | OF-OK | Oxygen-Free Electronic (OFE) Copper |

| C10200 | UNS C10200 | OF-Cu | Oxygen-Free (OF) Copper |

| C28000 | UNS C28000 | CuZn40 | Muntz Metal |

| C14500 | UNS C14500 | TeCu | Tellurium Copper |

Stainless Steel

Stainless steel is known for its strength, heat, and corrosion resistance, along with its durability and attractive appearance. These qualities make it suitable for a wide range of uses, including kitchenware, medical instruments, and construction.

| Stainless Steel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 316L | UNS S31603 | X2CrNiMo17-12-2 | Stainless Steel 316L |

| 304 | UNS S30400 | X5CrNi18-10 | Stainless Steel 304 |

| 17-4 PH | UNS S17400 | X5CrNiCuNb16-4 | Stainless Steel 17-4 PH |

| 303 | UNS S30300 | X8CrNiS18-9 | Stainless Steel 303 |

| 420 | UNS S42000 | X20Cr13 | Stainless Steel 420 |

| 440C | UNS S44004 | X105CrMo17 | Stainless Steel 440C |

Aluminum

Aluminum alloys are lightweight and strong, with excellent thermal and electrical conductivity. They are also resistant to corrosion and can be anodized for added protection, making them ideal for aerospace and packaging industries.

| Aluminum Alloy | UNS Designation | DIN Designation | ISO Designation |

|---|---|---|---|

| 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu |

| 6082-T651 | 3.2315 | 64430 | AlSi1MgMn |

| 6060 | 3.3206 | EN AW-6060 | AlMgSi |

| 5052 | EN AW-5052 | 3.3523 | AlMg2,5 |

| 2017A | 3.1325 | 24530 | AlCu4MgSi |

Inconel

Inconel is a strong, corrosion-resistant nickel alloy, ideal for challenging aerospace applications. It can withstand extreme temperatures and pressures, making it suitable for jet engines and gas turbines.

| Inconel | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 718 | UNS N07718 | 2.4668 | NiCr19Fe19Nb5Mo3 |

| 625 | UNS N06625 | 2.4856 | NiCr22Mo9Nb |

| 600 | UNS N06600 | 2.4816 | NiCr15Fe |

| X-750 | UNS N07750 | 2.4669 | NiCr15Fe7TiAl |

| 601 | UNS N06601 | 2.4851 | NiCr23Fe |

| 725 | UNS N07725 | 2.4668 | NiCr19Fe19Nb5Mo3 |

Invar

Invar is a nickel alloy with very low thermal expansion, making it highly stable and perfect for precision applications such as instrumentation and aerostructure molds. It is also used in scientific instruments where dimensional stability is critical.

| Invar | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 36 | UNS K93600 | 1.3912 | FeNi36 |

| 42 | UNS K94200 | 1.3917 | FeNi42 |

| 48 | UNS K94800 | 1.3922 | FeNi48 |

| 32-5 | UNS K94610 | 1.3911 | FeNi32-5 |

| 42-6 | UNS K94620 | 1.3913 | FeNi42-6 |

| 46 | UNS K94630 | 1.3914 | FeNi46 |

Titanium

Titanium is a lightweight metal with excellent strength, low thermal expansion, and high corrosion resistance. Its ability to be sterilized and its biocompatibility make it unique, especially in medical implants and aerospace components.

| Titanium Grade | UNS Designation | DIN Designation | Alternative Designation |

|---|---|---|---|

| 5 (Ti-6Al-4V) | UNS R56400 | 3.7165 | Ti-6Al-4V |

| 2 | UNS R50400 | 3.7035 | CP Titanium |

| 23 (Ti-6Al-4V ELI) | UNS R56401 | 3.7165 | Ti-6Al-4V ELI |

| 9 (Ti-3Al-2.5V) | UNS R56320 | 3.7195 | Ti-3Al-2.5V |

| 7 (Ti-0.2Pd) | UNS R52400 | 3.7235 | Ti-0.2Pd |

| 12 (Ti-0.3Mo-0.8Ni) | UNS R53400 | 3.7105 | Ti-0.3Mo-0.8Ni |

Kovar

Kovar is known for its exceptional thermal stability and precise expansion properties, along with its strength and compatibility with glass-to-metal sealing. These qualities make it ideal for specialized applications in electronics, aerospace, and medical devices.

Military & Defense Machining Tolerances & Capabilities

| Machining Service | 5-Axis Machining | EDM Machining | Mill-Turn Machining | CNC Lathes/Turning | Metal 3D Printed Parts |

|---|---|---|---|---|---|

| Maximum Part size | 28" x 24" x 15" | 13.5" x 21.5" | 14" dia x 16" oal | 10" dia x 10" oal | 28" x 24" x 15" |

| Standard Lead Time | 12 weeks | 12 weeks | 12 weeks | 10 weeks | 12 weeks |

| General Tolerances | .001" | .0005" | .0025" | .0025" | .001" |

| Precision Tolerances | .0001" | .00005" | .0005" | .00025" | .0001" |

| Minimum Feature Size | 250 x .250 x .250 | .01 x .01 x .01 | .060" dia x .050" oal | .060" dia x .050" oal | .250 x .250 x .250 |

| Minimum Surface Finish | 8 | 8 | 8 | 8 | 8 |

| Standard Surface Finish | 64 | 32 | 32 | 32 | 32 |

*Standard delivery is dependent on workloads. Call Owens for current lead times.

5 Axis Milling for Unmatched Precision and Accuracy of Military Parts

Owens Industries provides 5-axis machining services for highly detailed military components and micromachining for extreme accuracy at any scale. We also offer deburring and finishing to support flawless function in the field.

When your application demands tight tolerances, intricate geometries and absolute repeatability, our ultra-precision machine shop delivers. Partner with Owens for long-term support across your full range of CNC machining needs.

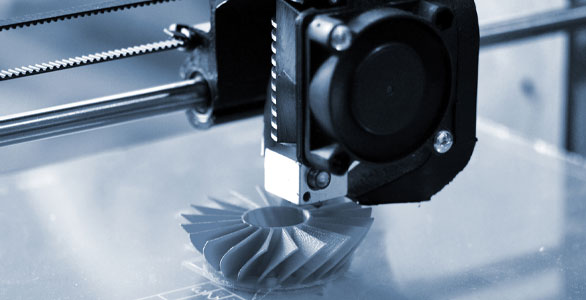

Additive Manufacturing for Military & Defense

Mission-Ready Metal 3D Printing

Owens Industries supplies precision metal 3D printed parts for critical defense systems. We produce components with complex internal features, reduced weight and extreme material performance—all essential for modern military platforms.

Working with alloys like rhenium, Inconel and cobalt-rhenium, we support applications ranging from propulsion and guidance systems to rugged field equipment. Every part is built, finished, and inspected in our AS9100- and ITAR-certified facility for reliable, real-world deployment.

Components We Build for the Military/Defense Industries

Let Owens Industries be the difference-maker on your next military or defense project. With decades of experience and proven results, we’ve earned the trust of defense leaders like HEICO, Boeing, SNC, Lockheed Martin, Raytheon, AMTEK and Parker with high-quality components like.

| Part | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|

| Load Sleeve | Cable Clamp | 5 Axis Profile Milling | Custom 455 Cond H1000 | Saddle Shaped Internal Profile |

| Pawl | Carriage Lock | 4-Axis Milling | SAE 8620 Alloy Steel | Milling Convoluted Profile |

| Blade, Cutter | Cutting Safety Cable | 5-Axis Milling | 17-4Ph Hardened | Keen Damage-Free Cutting Edge |

| Pivot Ball | Military Aircraft | Turning and Spot Welding | 316 Stainless Steel | Welding Carbide Ball to Stainless Steel Stem |

| Paddle | Actuator Arm | 4-Axis Machining | 6061-T6511 Aluminum | Milling 0.020" Thick Webs with 0.002" Flatness |

| Pawl, Leg Lock | Antenna Base | Conventional Milling | 17-4 Ph Cond H900 | Milling Fine Pitched Gripper Teeth |

| Shell Receptacle, 100 Pin | Connector High Temp | 3-Axis Milling | Kovar IAW AMS -I-25011 Class 1 | (100) 0.0445" Diameter Thru Holes |

| Plenum Base | Fuel Flow | Wire EDM | 6LA-4v Titanium per AMS 4928 | Machine 0.010" Thick Tube Wall |

| Actuator, Arm | Night Vision Goggles | EDM Wire | 17-4PH Stainless Steel Cond A | 20 Tooth Ratchet Profile |

| Cutter | Parachute Wire Cutter | 3-Axis Milling | Hardened O1 Tool Steel | Maintaining 0.010" Cutting Edge in V-Groove |

| Read Head | Signal Encoder | 5-Axis Milling and Grinding | 416 Stainless Steel Cond A | Precision Grinding of Flat Surfaces |

| Release Clip | Weapon System Pivot Assembly | 3-Axis Gang Milling | 17-4 ph Casting | Production Run Milling |

Contact Owens today to discuss your military and defense component needs.

View our Success Gallery to see our work!