Comparing 3-Axis, 4-Axis, and 5-Axis Milling

The main difference between 3, 4 and 5-axis milling is the complexity of movement and the parts they can produce. A 3-axis mill moves a cutting tool along three linear axes (X, Y, and Z) to create simple parts. 4-axis milling adds a rotational axis, which allows for more detailed work. 5-axis milling introduces a second rotational axis, enabling the creation of the most intricate and precise components with maximum efficiency. As the number of axes increases, so does the mill's ability to handle complex geometries without needing to be reset.

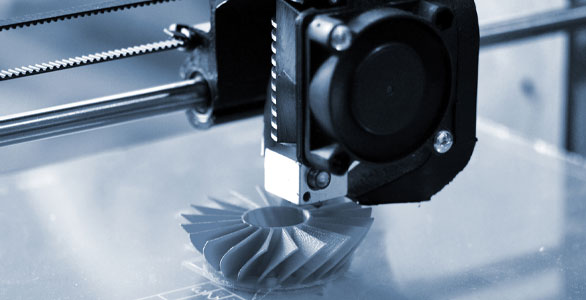

3-Axis Machining is the Most Widely Used Technique

Evolved from the practice of rotary filling, 3-axis machining is an average manual milling technique cutting parts on three axes; the X, Y, and Z axes. Invented in the 1800s, the vertical 3-axis CNC milling machine has come a long way in its capabilities. While many machines have a moving bed, the 3-axis milling centers are still while the cutter itself operates instead. 3-axis models are multifunctional, accurate machines designed for:

- Automatic/Interactive Operation

- Milling Slots

- Drilling Holes

- Cutting Sharp Edges

3-axis milling is capable of creating the same products as 4-axis and 5-axis machines, but the 3-axis machines cannot deliver the same level of detail or efficiency as its predecessors. 3-axis can cut individual features during operations, but it cannot match the work of a 5-axis in quality or profitability.

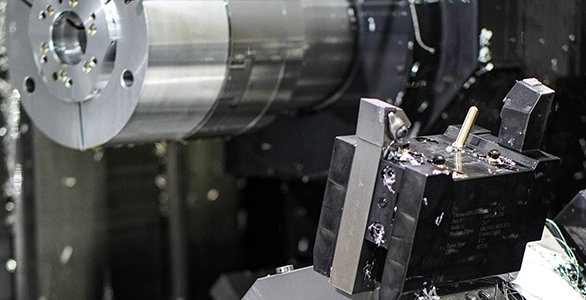

4-Axis Machining Provides More Detailed Cutting than 3-Axis

Similar to the 3-Axis CNC vertical milling machine, 4-axis micro-milling machines are vertically operated and built to function in a timely fashion. They are user-friendly with manual and computer lead operations. Built for detail work and accuracy, 4-axis is a step away from the high quality, precise engravings, drillings and millings of a 5-axis machine. Despite its shortcomings, the 4-axis CNC machine can be used for different purposes, including:

- Industry

- Technology Research

- Teaching

- Advertising Design

- Creating Art

- Medical Equipment Creation

With the ability to operate on wood, foam, composite board, aluminum alloy and even PCB, 4-axis is a multi-use CNC tool functioning at a slightly higher competency than the 3-axis.

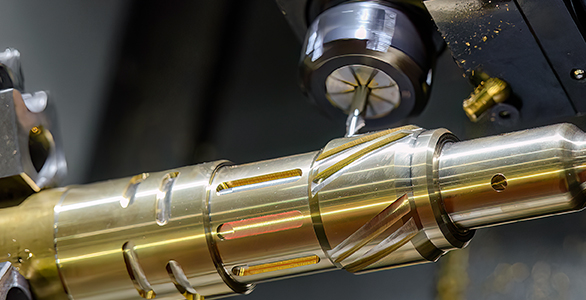

5-Axis is the Most Precise CNC Machining Process Available

The best CNC milling machine available today, 5-axis milling is a fast-working, precise, micromachining powerhouse. Owens Industries specializes in 5-axis machining because of its superior functions compared to the 3-axis and 4-axis CNC Machines. A 21st-century marvel, 5-axis CNC machines are capable of impeccable product and parts creation. This extremely fast milling machine, unlike the 3-axis and 4-axis, has the capabilities to efficiently and impressively produce:

- Artificial Bones

- Aerospace Products

- Titanium Creations – For Both Practical and Artistic Purposes

- Oil and Gas Machine Parts

- Car Molds

- Medical Technology

- Architectural Door Frames

- Military Grade Products

5-axis CNC is capable of cutting the most complex and tedious designs existing in the world. It can operate much faster than 3-axis and 4-axis CNC machines and provide vertical milling with the highest precision and quality available today.

Get Multi-Axis Machining Services from the Professionals at Owens Industries

The professional CNC engineers at Owens Industries can manufacture precision parts for you to your exact specifications. We machine components for a wide variety of industries all over the United States – no matter if you’re looking for specific components for your medical clinic or aircraft parts for an aerospace company, we use only the best multi-axis milling equipment to build your parts to the most precise accuracy.

Not only multi-axis milling, but the professionals at Owens Industries provide the following services:

See Owens Industries' 5-axis milling center at work in the video below:

Contact our CNC Machine Shop for a quote on your 5-axis milling needs!

Happy with our service? Leave us a 5-star review!